Mild PEB Modular Metal Developing Framing Roll Forming YWIN

| Light Gauge Metal House Frames Roll Forming YWIN |

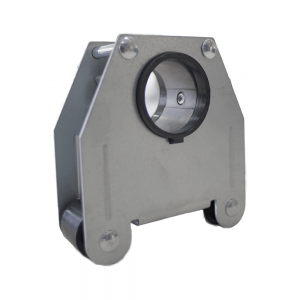

Product:JCX-02 | Dimension:89*41*10 | Driving Approach Servo Motor |

||||||||

| ,Specification | |||||||||||

| 1 | Main roll forming equipment | Feeding unit | With 4 guiding rollers | ||||||||

| Roll forming gadget | 12 roller stations, a single is to sort and alter the angle ( from 87 to 95) degree of bottom and net | ||||||||||

| Straightening gadget | With a single pair of horizontal shafts and two dangling rollers | ||||||||||

| Profile foremost device | With one particular established of top rollers | ||||||||||

| Punching holes | |||||||||||

| Also have three holes at the finish of profile | |||||||||||

| Cutting device | 3 parts of blades to preserve and reduce the condition of profile | ||||||||||

| 2 | Manage method | Main control method | One particular Lenovo notebook and a control box inside of based mostly frames of the equipment | ||||||||

| Creating software | Particular developed to match with the designing software program Vertext | ||||||||||

| Leaser Printing System | Usa Matthews Leaser Printing Unit for painting spray symbol and installation indicating variety | ||||||||||

| Distant-management gadget | Wi-fi remote-controller controls device to go forward or backward or stop | ||||||||||

| Manufacturers of major elements | PLC(self-designed),Relay (French Schneider), proximity switch(French Schneider), Encoder(Japanese Omron), Servo Motor(Montreale) All individuals factors requires with Internation Warranty Service. |

||||||||||

| 3 | Servo Program and YWIN System | Servo motor | five.5kw, having with precision planetary gear reducer | ||||||||

| YWIN Station | seven.5KW | ||||||||||

| YWIN oil injection 200 litre | |||||||||||

| Makes of principal elements | solenoid valve (Germanic YWIN) |

||||||||||

| four | Electric powered decoiler | bearing capacity | 3 ton | ||||||||

| Expending or shrinking method | Function the take care of to a lot more the 4 link rods to away from or shut up to the cored shaft | ||||||||||

| brake | Cored shaft is double hold tightly | ||||||||||

| Driving strategy | Decoil raw material routinely | ||||||||||

| 5 | Manufacturing acquiring System | length | 4m | ||||||||

| Acquiring approach | Get shaped profiles and sideslip them pneumatically to preserving desk | ||||||||||

| 6 | Parameters of roll forming component | roller | Content: GCr15 | ||||||||

| processing technic:CNC machining, warmth therapy HRC58-60,then processed by CNC lathe, plating last but not least | |||||||||||

| shaft | Substance: 40Cr | ||||||||||

| processing technic:CNC machining, quenching and tempering HRC28-32,then processed by CNC lathe, plating and polishing finally | |||||||||||

| weight | About three.5 ton | ||||||||||

| ,parameters of fashioned profiles | |||||||||||

| one | Measurements |

|

|||||||||

| two | Forming velocity | The max speed 35m/min, usually two-3 tons per working day | |||||||||

| 3 | material | Q345,G550 galvanized steel strip | |||||||||

| ,connected factors and spare areas | |||||||||||

| Spare components | 2 sets of punching poles and down moulds | instruments | One established | ||||||||

| Guide procedure | 1 duplicate | Protecting include | completely-enclosed kind | ||||||||

| YWIN shade | As for each device photographs or your demand | ||||||||||