TSH-75B Twin Screw Plastic Pellet Extruder Generation Line

About Product

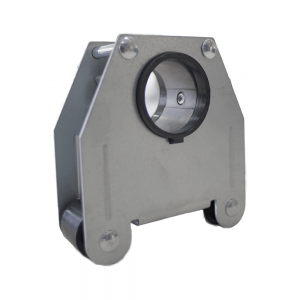

Principal machine

Product Specification

| Kind | Dia.(mm) | L/D | Pace(rpm) | Motor(KW) | Torque(N.M) | Output(kg/Hr) |

| TSH-20 | 22 | 32-60 | 400 | 3 | 4.8 | 2~ten |

| 600 | 4 | four.eight | 2~fifteen | |||

| TSH-thirty | thirty | 32-fifty six | 400 | seven.five | 4.8 | ten~30 |

| 500 | eleven | 4.8 | ten~forty | |||

| 600 | fifteen | six.6 | fifteen~55 | |||

| TSH-35 | 35.six | 32-sixty | 400 | 11 | 4.six | ten~40 |

| 500 | fifteen | 4.two | fifteen~fifty five | |||

| 600 | 22 | six.one | forty~ninety five | |||

| TSH-forty | forty one | 32-sixty | 400 | 22 | 6. | 40~95 |

| 500 | thirty | five.five | 70~120 | |||

| 600 | 37 | 6.eight | ninety~150 | |||

| TSH-fifty two | fifty one.4 | 32-60 | 400 | 45 | five.1 | 120~200 |

| five hundred | 55 | 5.2 | 155~255 | |||

| 600 | 75 | 7.1 | 200~355 | |||

| TSH-65 | 62.four | 32-sixty | 400 | 55 | four.eight | two hundred~355 |

| five hundred | 75 | four.eight | 255~400 | |||

| 600 | 90 | 5.9 | 300~550 | |||

| TSH-seventy five | seventy one | 32-sixty four | four hundred | 110 | four.6 | three hundred~550 |

| five hundred | 132 | 4.six | 450~750 | |||

| 600 | 160 | five.five | five hundred~850 | |||

| TSH-eighty five | eighty one | 32-sixty four | 500 | 200 | five.eight | 600~a thousand |

| 600 | 220 | 5.3 | 650~1100 | |||

| 600 | 280 | 6.seven | 850~1400 | |||

| TSH-95 | 93 | 32-sixty four | 500 | 250 | 4.7 | 750~1250 |

| 600 | 315 | 5. | 950~1600 | |||

| 600 | 450 | 7.one | 1350~2250 | |||

| TSH-one hundred twenty | 116 | 32-fifty six | four hundred | 315 | 4.4 | 950~1600 |

| five hundred | 450 | five. | 1350~2250 | |||

| five hundred | 550 | 6.1 | 1800~3000 | |||

| TSH-a hundred thirty five | 133 | 32-48 | 400 | 550 | four.4 | 1650~2750 |

| five hundred | 750 | five. | 2250~3750 | |||

| five hundred | 900 | 6.1 | 3000~5000 |

Technical characteristics:

TSH Series Co-rotating Twin Screw Extruder are widely used in the compounding modification field, like the filling,

reinforcement,toughening of plastics, engineer plastics and thermoplastics,and also for the special fibers and adhesive process.

Main products are classified as TSH & TDH series,according to the max screw rpm and its torque rating.

All models and parts have been upgraded with modernize CNC equipment.

Our customers will have whole products range to meet their unique requirements.As the segment structure design,

the equipment can be configured with different L/D,barrel designs, screen changer, pelletizing system, and/or electric control,

to best meet unique requirements of different process.Cause our better understanding of the different material,

the screw configuration is designed based on rich experience and software technology to accomplish the material conveying,

plasticizing compounding,shear and dispersion and pressurization. Screw elements, accurately designed with CNC technology,

are fully intermeshed, providing self-cleaning and easy interchangeability.Upgrading accuracy and quality of the standard and high torque gear box.

The special new type barrel structure and screw elements been manufactured with our powerful design experience.

Application material

Fiber reinforcement: PP PA PBT Abdominal muscles Pc POM PET and many others with glass fiber, carbon fiber

Polymer blending: Pc+Abs, PA+Ab muscles, PP+EPDM, PA+ EPDM and many others

Cable compounding: cable insulation compounding of LDPE HSPE LLDPE MDPE and so forth

Large focus color masterbatch: PE Abdominal muscles PS EVA PP and many others with flame retardants and other additives

Specific purposeful masterbatch: masterbatch with anti-static, anti-microorganisms, or other specific functional fillers

Masterbatch for degradable polymer: PP PE PS and so on with substantial concentration of starch and other additives.

About Company

Tenda , headquartered in Montreal, China, is a global manufacturing and trading company in the field of high

performance plastics and rubber processing equipment , extrusion solutions, masterbatch and compounding, etc.

It is a professional manufacturer of twin screw extruder, single screw extruder ,two stage extruder and

its related auxiliaries.We tailor solutions from raw materials, materials processing equipment,

to injection for different customers. Each solution is designed , manufactured, and commissioned by

experienced teams of professionals engineers and after sales staffs. “High efficiency, energy-preserving”

is the company since its inception has been diligently pursue the goal, is the company adhere to the invariant features,

to meet customer requirements, to create greater economic benefit and social benefit.

“Teng machinery” will strive to create superior machine quality, permanent service for you.

Packing & Delivery

Our device is to begin with painted with anticorrosive oil, and then wrapped in the plastic film ahead of it is finally packed in the wooden situation or container.

Packing: wood case for export, in shape for numerous handing and long length marine transport.

Manufacturing time: within forty five perform days.

Q&A

one.Why choose us?

You can get a very fair price from us and our price can make you beat your competitors in the market.

Our products have obtained ISO9001 and CE certification,the quality can be guaranteed.

We use the best quality materials or imported materials.

We focus on the field of extrusion machine,and aim to be the best manufacturer of this field.

We can reply quickly for customers’ demand and the delivery can be very fast.

We have our own factory and the technical production team,the workers are all very experienced.

2.How about the service?

Before sales

one. introduce products and application details

2.recommend suitable solutions

three. provide with reference information

During manufacturing

one. provide with layout and engineering conditions

2.inform the processing conditions

3. offer other documents

After Sales

1.provide with installation and training

2.offer spare parts

three. provide with necessary technical support

three.What’s the payment?

L/C, T/T, Western Union, Paypal, Money Gram.