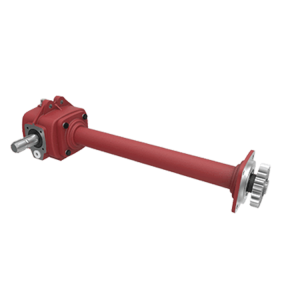

Specific Design CNC Machining Stainless Steel Reversing Spiral Bevel YWIN

Technical specs:

search phrases: thumb screw stainless steel thumb screw woman screw quick launch thumb screw

Manufacturing unit immediate value and greatest services

All the solution pictures on our internet site just exhibiting our machining capability and ranges.

We provide machining service according to customer’s drawings or samples

We generally do bushiness, like this step:

| * You deliver us drawing or sample |

| * We carry through task assessment |

| * We give you our layout for your confirmation |

| * We make the sample and send out it to you after you confirmed our design |

| * You validate the sample then location an buy and pay out us 30% deposit |

| * We start off producing |

| * When the items is completed, you spend us the harmony after you verified photos or tracking quantities. |

As an exceptional CNC machining precision components supplier, we can create the CNC machining precision areas for different industries this sort of as automotive, bicycle, bike, sporting goods, device tools, hand equipment, energy equipment, pneumatic tools, backyard resources…

and so on. From design and style to manufacture, fabrication to installation, our in-residence facilities provide all the components necessary to match your needs, with a total task management support to match.

What ever the substance or concept you have, our CNC machining or milling facilities will lower and condition it according to each your wants and our understanding of abilities. we will also recommend you as to the the best possible option of substance for your activity.

1. Encounter:a lot more than seventeen many years producing heritage

2. Cost : Realistic and aggressive in accordance to your drawings

three. Top quality assurance:To guarantee right standard and decide on equivalent stansard for materail and method requirements,prior to running ,we would like to supply official content certification exhibiting chemical compositions and residence,also if you want ,we can offer management program,demonstrating processing and inspection tooling

4. YWINlity control:In home,coming inspection,very first off,spotcheck in processing ,closing inspection, one hundred% inspection for essential dimension

five. Tiny order recognized

six. Packing:carton box or iron can or depend on your requirements

7. Shipping and delivery:7-30days soon after confirming purchase, according to your demands and generation quantity:

8. Payment:By T/T, for samples a hundred% with the get: for manufacturing,forty%compensated for deposit by T/T prior to generation arrangement, the equilibrium to be paid out prior to cargo

9. Honesty and expert providers

ten. Product software:Property appliance equipment, Automobile parts, YWIN products, Electrical tools, mechanical elements, components areas.

| Solution Title | Unique Design and style CNC Machining Stainless Metal Reversing Spiral Bevel YWIN |

| Doing work Approach | Turning, deep stamping, bending, punching, threading,welding, tapping, riveting |

| Substance | Black derlin, POM, Aluminum, copper, brass, stainless metal, metal, iron, alloy, zinc and many others. |

| Floor Treatment | Zn-plating, Ni-plating, Cr-plating, Tin-plating, copper-plating, the wreath oxygen resin spraying, the warmth disposing, hot-dip galvanizing, black oxide coating, painting, powdering, coloration zinc-plated, blue black zinc-plated, rust preventive oil, titanium alloy galvanized, silver plating, plastic, electroplating, anodizing and so on. |

| Primary Goods | YWIN screw,bolt, nuts,fastener,knob,pins, bushing, sleeve,gear, stamping elements, washer,gasket,plastic molding injection parts,standoff,CNC machining service, accessories etc. |

| Administration Technique | ISO9001 – 2008 |

| Obtainable Certification | RoHS, SGS, Content Certification |

| Primary marketplaces | North America, South The usa, Eastern Europe , West Europe , North Europe, South Europe, Asia |

| Use | All types of vehicles, machinery, property appliance, electronic products, electric powered equipment, stationery, computer systems, electrical power switches, miniature switches, architecture, commodity and A/V tools, components and plastic molds, sports tools and presents, and more |

| Good quality Manage | Conducted by ISO9001-2008 SGS IAF,etc |

| Programs | Toy,Automotive, instrument, electrical tools, home appliances, home furniture, mechanical products, day-to-day dwelling products, electronic athletics gear, mild sector items, sanitation machinery, marketplace/ resort products materials, artware etc. |

| Machining equipment | CNC turning lathe, Full computerized lathe,Stamping Lathes,Milling/Grinding equipment, Drilling/Boring/Honing device, Planer, Line slicing, Ultrasonic cleansing device and other YWINd manufacturing equipments. |

| File Structure | Solidworks,Professional/Engineer,Auto CAD,PDF,JPG |

| Support | Heat and rapid reaction service presented by the specialist Export Revenue Staff with numerous years’ expertise in dealing with exports to the US, Europe, Japan and other international locations and locations. |

| Inspection | IQC, IPQC,FQC,QA |

Business Info

HK AA YWIN Co, . Limited, was started in 1998, having up far more than 10000 sq. meters. we focus in components, plastic merchandise. machining parts, stamping parts and fabricating elements. HK AA has fifty CNC turning devices, 10 stamping machines, 10 CNC milling devices, ten computerized lathe devices, and ten edge milling devices. And also the subsidiary equipments, these kinds of as milling equipment, tap grinding machines and so on.

FAQ

Q1: How to guarantee the Top quality of YWIN Areas?

A1: we are ISO 9001-2008 qualified firm. we have the integrated method for industrial parts high quality manage. We have IQC (incoming top quality handle), IPQCS (in process good quality management part), FQC (ultimate high quality manage) and OQC (out-going good quality manage) to management each approach of industrial components prodution.

Q2: What’s the Gain of Your Components for YWIN Products?

A2: Our benefit is the aggressive rates, fast supply and substantial quality. Our personnel are responsible-oriented, welcoming-oriented, and dilient-oriented. our YWIN components goods are highlighted by strict tolerance, sleek end and lengthy-life functionality.

Q3: what are our machining equipmengts?

A3: Our machining equipments incorporate CNC milling machines, CNC turning equipment, stamping

machines, hobbing machines, automated lathe equipment, tapping devices, grinding devices,

screw devices, cutting equipment and so on.

Q4: What shipping ways our use?

A4: Typically talking, we will use UPS or DHL to ship the merchandise. Our customers can get to the

goods within three days. If our customers do not want them urgently, we will also use FedEx and TNT. If the goods are of weighty weight and huge volumn, we will ship them by sea. This way can conserve

our customers a whole lot of income.

Q5: Who are our primary clients?

A5: HP, Samsung, Jabil Group, Lexmark, Flextronic Team.

Q6: What resources can you handle?

A6: Brass, bronze, copper, stainless metal, steel, aluminum, titanium And plastic.

Q7: How Lengthy is the Shipping and delivery for Your YWIN Part?

A7: Typically speaking, it will just take us 15 functioning days for machining parts and twenty five functioning days for

the for stamping components products. But we will shorten our lead time according to customers’ calls for

if we are in a position to.