Prefabricated Steel Channel Villa Property Body YWIN With Vertex BD

| Light Gauge Metal Property Frames Roll Forming YWIN |

Design:JCX-02 | Measurement:89*41*10 | Driving Approach Servo Motor |

||||||||

| ,Specification | |||||||||||

| one | Main roll forming equipment | Feeding system | With four guiding rollers | ||||||||

| Roll forming gadget | 12 roller stations, one particular is to kind and modify the angle ( from 87 to ninety five) diploma of base and world wide web | ||||||||||

| Straightening unit | With one particular pair of horizontal shafts and two dangling rollers | ||||||||||

| Profile top unit | With one established of leading rollers | ||||||||||

| Punching holes | |||||||||||

| Also have 3 holes at the finish of profile | |||||||||||

| Chopping device | three pieces of blades to keep and minimize the form of profile | ||||||||||

| 2 | Control system | Primary handle technique | One particular Lenovo notebook and a management box within of based mostly frames of the equipment | ||||||||

| Making software | Special designed to match with the developing software program Vertext | ||||||||||

| Leaser Printing System | Usa Matthews Leaser Printing Gadget for painting spray brand and set up indicating quantity | ||||||||||

| Distant-management unit | Wireless distant-controller controls device to go ahead or backward or quit | ||||||||||

| Manufacturers of primary elements | PLC(self-designed),Relay (French Schneider), proximity switch(French Schneider), Encoder(Japanese Omron), Servo Motor(Montreale) All those parts will take with Internation Warranty Service. |

||||||||||

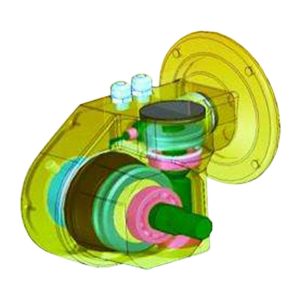

| three | Servo Method and YWIN Method | Servo motor | five.5kw, using with precision planetary gear reducer | ||||||||

| YWIN Station | seven.5KW | ||||||||||

| YWIN oil injection 200 litre | |||||||||||

| Manufacturers of principal parts | solenoid valve (Germanic YWIN) |

||||||||||

| 4 | Electric powered decoiler | bearing capacity | 3 ton | ||||||||

| Expending or shrinking approach | Operate the manage to much more the 4 connection rods to away from or shut up to the cored shaft | ||||||||||

| brake | Cored shaft is double keep tightly | ||||||||||

| Driving strategy | Decoil raw content instantly | ||||||||||

| five | Creation getting System | duration | 4m | ||||||||

| Receiving technique | Acquire shaped profiles and sideslip them pneumatically to saving table | ||||||||||

| six | Parameters of roll forming part | roller | Content: GCr15 | ||||||||

| processing technic:CNC machining, heat treatment HRC58-sixty,then processed by CNC lathe, plating lastly | |||||||||||

| shaft | Substance: 40Cr | ||||||||||

| processing technic:CNC machining, quenching and tempering HRC28-32,then processed by CNC lathe, plating and polishing finally | |||||||||||

| fat | About 3.5 ton | ||||||||||

| ,parameters of formed profiles | |||||||||||

| one | Sizes |

|

|||||||||

| two | Forming velocity | The max speed 35m/min, normally two-3 tons for each day | |||||||||

| 3 | material | Q345,G550 galvanized metal strip | |||||||||

| ,attached parts and spare elements | |||||||||||

| Spare components | 2 sets of punching poles and down moulds | tools | 1 set | ||||||||

| Manual procedure | One copy | Protective protect | totally-enclosed type | ||||||||

| YWIN color | As for every equipment images or your demand from customers | ||||||||||