We are a manufacturing facility specialized in metal areas components & metal gearbox via powder metallurgy approach .

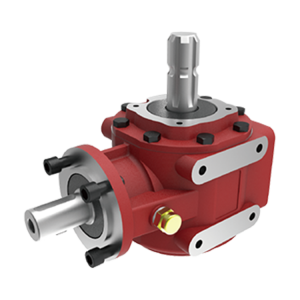

A gearbox is a electrical power transmission gadget to produce substantial torque by reducing the generate velocity or enhance the push velocity the other way. Planetary gearbox consisting a few factors: sun gear, earth gear and ring equipment . A Solar equipment is a gearwheel in a planetary gear method, that rotates close to its very own axis and has other gears (earth gears) that rotate close to it. Considerably like the Sunshine and planets in our solar program. The quantity of planetary gears in a gearbox differs based mostly on the gear ratio. Most planetary gearboxes have from two to five earth gears. When searching at planetary gears, the power of the gearbox is typically determined by the size of the sun equipment. Bigger solar gears will let for increased torque values. The world provider,Its goal is to maintain up to gears of the same size, which mesh with the solar equipment.

Planetary YWIN benefits:

- Supplies high torque at gradual speeds .

- The shafts are made up of hardened and tempered alloy metal .

- Sunshine gears ,earth gears and ring gears are created of powder metallurgy and sintering metal .

- Reduced sound stages.

- Great high quality taper roller bearings for enter and output shafts .

- Large performance .

PM method for customized steel planetary gearbox , geared motors .

The P/M method is an cost-effective, environmentally thoroughly clean, large production technique for generating parts just to or near to final dimensions. With small or no machining functions essential.

At current, parts with a difficult form, restricted-dimensional tolerances, managed density and homes can be produced by powder metallurgy techniques. A technological approach of powder metallurgy guarantees high overall flexibility in the choice of physiochemical homes and other specifications, including:

- Production of structural elements with complex styles .

- Managed porosity .

- High mechanical toughness and resistance to vibrations .

- Controlled houses.

- High mechanical strength and resistance to vibrations.

- Large producing precision and great floor good quality

- Big amount of generation collection .

- Good tolerances .

There are three fundamental actions to powder metallurgy, the process utilized to generate powder steel gears. Initial, any of a amount of techniques such as atomization, flaking, pulverization, chemical reduction and electrolytic are utilized to reduce the first raw metallic materials to a fantastic dust or powder. Distinct amounts of this powder are then placed into the compaction die or mold where force is utilized from the two previously mentioned and under in precise quantities pertinent to the certain resources and intended use of the concluded equipment. This mold is pre-fashioned and results in the sought after equipment form. Right after this kind is ejected from the die, sintering is utilised to fuse the powder particles with each other.Sintering is a heat treatment commonly utilized to increase the energy and structural integrity of a presented materials. Powder metallurgy processes use sintering to change steel powders and other distinctive supplies into stop-use components. Sintering typically takes area in a one, elongated furnace with distinct temperature zones.

YWIN steel components

Workshop