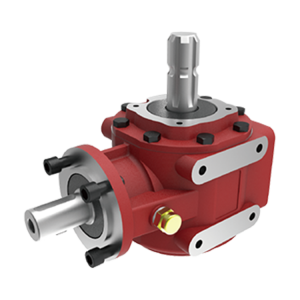

Speed rising gear box of 135m ending mill

Composition of speed increasing gearbox

Spare areas of velocity growing gearbox circumstance&lparlower case&comma center circumstance and cover&rpar&comma assist foundation&comma massive gear&comma transmission axis&comma bevel wheel and lubrication program&interval

Technical characteristics

Box is soften with thick metal with excellent top quality to achieve the intensity that the scenario essential&interval Case ought to take stress getting older treatment prior to the create to achieve the security that needed&interval High precision lathe machining is used for the assembly of situations to insure the finding precision of each bearing holes and connected joint surface area&period

Massive gears and gear shaft employed carbon alloy steel forging blank&comma soon after roughing&comma workpiece want to consider ultrasonic flaw detection procedure to quench&interval In buy to make certain the tooth area with high hardness&comma tooth surface need to have to consider carburizing and quenching remedy soon after semi-finishing&period of time Wonderful grind of tooth surface to insure the substantial accuracy&comma right after finishing the manufacturing of gear&comma the harmony take a look at is needed&comma the trail speed is 1500r&solmin and the equilibrium precision quality is G2&period5&time period The trail pace of bevel wheel is 3500r&solmin&comma the balance precision quality is G1&comma in so to ensure the rotary precision of the gears&period of time

Transmission shaft use the alloy metal forging blank&comma transmission shaft normally takes quenched to make confident the depth and durableness&time period Right after the semi- ending&comma transmission need to grind to assure the precision of each workpiece&interval

When the assemble concluded&comma the no-loading examination need to be maintain 2-4hours&comma the pace is 1100r&solmin&comma the temperature of shaft ought to not exceed 40º C&comma the work of equipment ought to be easy&comma no hitting sound and concussion&comma each joint surface area need to not have oil spill phenomenon&period

| Item | Bevel gearbox for 90m ending mill group |

| After Revenue Support | Engineers Accessible to Services Overseas |

| assembled shaft pace | 4550 r / min |