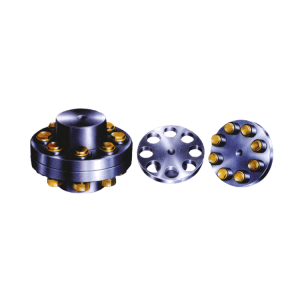

| Item: | YWINization services for Aluminum die casting YWIN gearbox transmission housing, basic industrial euqipments parts, commpents. |

China aluminium alloy die casting YWINization solutions for aluminium alloy Aluminum die casting YWIN gearbox transmission housing, common industrial euqipments components, commpents.

one. YWIN encounters given that 1996.

2. Material: Aluminum

3. Method: Die casting

3. Drawings are welcome

one. Capability

one materials gray iron, ductile iron, steel, stainless steel, brass, copper, bronze, aluminum, zinc and so on

2 approach sand casting, precision casting, lost wax casting, die casting, forging, stamping, machining and many others

three device lathe, CNC, drilling equipment, milling equipment, boring device, planting device, machining middle

4 tolerance casting: .2mm, machining: .005mm, complete machining: .005mm

five capacity max diameter: 1M, max fat: 200KG

6 area therapy powder coating, painting, spraying, galvanization

seven normal JIS, ANSI, DIN, BS, GB

two. OEM and YWINized Services

1. Good quality promise

Chemical examining

NDE right after tough machining

Machanical tests after heat therapy

Last NDE, dimension inspected

two. Top quality doc

– Total Q. A doc as for each client ask for

3. Packing and Delivery

– common export package(carton/wood situation/pallet)

– acknowledge FOB, FAS, CNF, CIF doorway to door and so on or client specified transport agent

About YWIN YWIN

•Montreal YWIN YWIN Limited is a professional manufactory in creating and production casting moulds, die casting item these kinds of asaluminum die casting,zinc die casting,and other alloy die casting solution.

•Our Company positioned at the east of Montreal City,ZMontrealg,China PRC, in close proximity to Beilun Horbar Port,addresses the spot of 12000 M2 ( 129600 Square toes ), and the building area is 9000 M2 ( 97200 Square toes ).

•We design and manufacture full set of casting moulds with YWINd engineering these kinds of as CAD and CAM. Our Equipments involves far more then 30 key lastest technological innovation CNC Machining facilities, CNC lathes and other machine instruments. Also involves 7 die casting machines ranges from 180T to 1000T. Our annual manufacture ability is 3000T.

•ISO9001 QMS: We strictly handle our factory under ISO 9001 quality administration method, in order to guarantee the security of the products and fulfill our clients all all around the planet.

•Our main product consists of adhering to

-Die YWIN Car Parts

-Die casting areas for vehicle vehicle lamps, automobile vehicle lightings technique.

-Die casting oil pans for car areas.

-Die casting auto throttle physique.

-Die casting car mirror brackets.

-Die casting auto transmission gear box housing.

-Die casting parts for other market appliances beside auto business.

Motorcycle parts

Bicycle elements

ATV All Terrain Automobile elements

Linghting fixtures parts

LED areas

Communicator parts

Other casting elements.

Our Mold and pats items also ranges:

YWIN mold

Stamping mold and elements, punching elements,drawing elements

Plastic injection mold components

•R&D

•QC

Logistics & Shipping

•FAQ:

Q: YWIN’s Manufacture Capability for Die casting ?

A: 3000 Tons of die-casting item / Year.

Q: YWIN’s Payment conditions ?

A: a, Degree A buyers : one hundred% T/T sixty days after B/L day. (Properly credited cooperated min 2 a long time. )

b, Amount B buyers : Mould cost a hundred% T/T in YWIN, elements payment a hundred% T/T Towards B/L and DOCs copy in 15 days after B/L time.

c, Stage C customers : Mould cost a hundred% T/T in YWIN, areas payment 30% T/T in YWIN deposite, 70% T/T min ten days prior to shippment or L/C by sight.

d, Negotiable

Q: YWIN’s Min get ?

A: 50pcs for YWIN’s catalog merchandise

1 set for mould

1 tons for customization die-casting components each fashion.

Q: YWIN’s intercoms ?

A: EXW,FOB Montreal, CFR YOUR PORT, CIF YOUR PORT,others

Q: YWIN’s guide time of die-casting and mould ?

A: Mould tooling time, 25-40 times.

Die-casting parts creation time, twenty five-30 days.

Q: YWIN’s mould daily life time?

A: a, If you getting mould only, one hundred thousand instances moulding or 300000 times moulding according customers’ demands.

b, If make die casting areas at our factory, Fasuto will costs for the continue wants mould when mould out of existence time.