Merchandise functions

Big spur gears are spherical steel disks with enamel cut close to the circumference. In buy for the equipment to qualify as a equipment, the tooth must be cut so that they operate perpendicular to the gear’s experience. Helical gears are the most straightforward style of gear produced. They are typically utilized for the transmission of rotary drive. For case in point, if two shafts are parallel to one particular an additional, and a single is spinning, a helical equipment can assist to transfer that drive onto the other shaft. Helical gears usually have an functioning efficiency of ninety eight% to ninety nine%.

1.Substance: C45 carbon metal,20CrMo,20CrMoTi,Stainless metal,brass,plastic,POM,and so on.

two.Moudle:M0.4-M10

three.Surface therapy: Galvanizing,zinc plating,Black oxide,Spray Printing, Mirror Finish, Burnishing, Sand-blasting and as your need.

4.Heat treatment:Hardening and Tempering,Substantial Frequency Quenching, Carburizing Quenching..

5.We can make all sorts of Gears according to clientele drawing and technical specs ,specializing in non-common items.

6.We can manufacture with various percision,this sort of as DIN6,DIN7,DIN8,and many others.

Requirements

– OEM support offered

– Outstanding quality at aggressive price

-YWINized

We can provide OEM Provider for Equipment Steel YWINs, and people steel castings can be developed in the pursuing conditions:

- Warmth treatment method: Normalized, Normalized and Tempered, Quenched and Tempered

- Machining: Tough machined, Semi-finished machined, Completed machined

- Non-Damaging Testing: Magnetic Particle Screening, Ultrasonic Tests, Penetrant Screening

- Materials: Carbon Steel, Alloy Metal, satisfy ASTM, BS, DIN, NF, JIS, ISO normal

- Specific Fat: 500KG – 140MT

Specialized parameters:

The Process As Comply with: ingot → warmth → forging → warmth remedy(normalizing+tempering) → inspection → rough machining → UT → 2nd warmth treatment method → finishing machining → inspection .

Top quality Control: UT,MT,RT,PT,chemical composition check,mechanical house check,etc.

Warmth Treatment method: Normalize,Quenching,Tempering,Anealled.

Floor Therapy: painting,plating,polishing,black oxide,transparent anti-rust oil.

Inspection: Besides our in-property inspecion, you could also choose a 3rd celebration inspection.

YWIN: ANSI,ASTM,ASME,API,JIS,DIN,BS,EN,KS,UNI,SABS,GOST.

Certificate: 1, Uncooked substance certificate(materials chemical compositon)

two, Heat remedy sheet report

three, Dimension inspection report

4, UT check report

Packing: Seaworthy plywood packaged on stell pallets or as customer’s request

Shipping Date: Decided by the amount and proportions of goods. Generally we manage the massive diameter rings’ supply time in five months after we get your official purchase.

Aggressive Gain: Quality manage and management to the entire generate process, including ingot smelting,forging, heat remedy, machining and strictly ultimate inspection prior to shipping and delivery.

| Process&Technological innovation of Metal YWINs | |

| Item | Introduction |

| Method | Sand YWIN |

| Machining | rough machining, semi-finished machining, completed machining |

| Examination | Chemical composition, mechanical home, UT,MT |

| Heat Treatment method | Normalized, Normalized and Tempered, Quench and Tempered |

These days our items can be identified in a lot of places throughout the world, like West Europe, South The us, Middle East, Australia, Southeast Asia.

Product Software

Semi-Automated PET Bottle Blowing YWIN Bottle Making YWIN Bottle Moulding YWIN PET Bottle Producing YWIN is ideal for producing PET plastic containers and bottles in all styles. It is widely utilized to generate the carbonated bottle, mineral water, pesticide bottle oil bottle cosmetics, vast-mouth bottle and hot fill bottle etc. Beverage bottle, cosmetic bottle, drugs bottle, jar etc.

roduct Specifics

Gear get in touch with location up to eighty% noise demands beneath 60 db heat treatment warmth remedy quenching hardness HRC58 to 62 depth of carburizing layer .eight to one.2um

| Solution Title | gear |

| Material | steel |

| Approach | casting |

| Floor Treatment | according to customer requirements |

| or Kubota combine harevest part, kubota tractor spare part | |

| Equipment | Apply to Kubota/yanmar/daedong elements |

| Design | For Kubota 481,488,588,688,688Q,DC60 and etc. |

| ITEM CONDITION | NEW |

For Kubota combine harevest spare parts,tractor areas

We are skilled provider for kubota combine harevest and tractor component amid which shafts,gears,Motor elements,casting elements,forging parts and and many others..are our fantastic benefits.

Our goods have protected far more than ten thousand types of components.Make sure you truly feel cost-free to make contact with us!!!

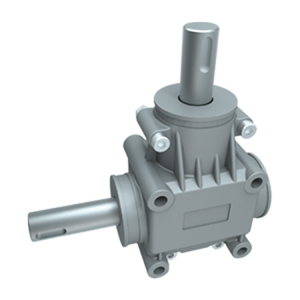

| roduct Name | YWIN YWIN Car Transmission Parts Helical Screw Equipment Maker |

| Substance | Carbon Stee:forty five#, SAE1 514 , SAE1045, Y15Pb, 1214L. |

| Alloy Metal:Cr12, 40Cr, 20CrMnTi, 16MnCr5, 20CrMnMo, 42CrMo, 17CrNiMo5… | |

| Brass/Bronze :HPb59-one, H70, CuZn39Pb2, CuZn40Pb2,C38000, CuZn40 | |

| Iron:Grey iron and ductile iron | |

| Aluminum:6061, 6063,7075,5052 etc. | |

| Forged Metal:Common carbon metal, alloy steel, stainless metal, etc | |

| Coloration | OEM |

| YWIN | DIN GB ISO JIS BA ANSI |

| Grade | SUS201, SUS304, SUS316, A2-70, A2-eighty, A4-80, four.eight 6.8 eight.eight 10.9 12.9 |

| Surface Treatment | Blacking, sharpening, anodization, anodized, passivation, portray, energy coating, black oxide, silver/gold plating, electrolytic sharpening, nitrided, phosphating, sandblasting, nickel/zinc/chrome plating, and many others.Rock |

| Treatment | Quenching & Tempering, Carburizing & Quenching, Large-frequency hardening, Carburization, etc. |

| Employed | YWIN tools, outboard motors, machine equipment, lawn and backyard equipment, maritime hoists, multi-spindle drives, snow throwers, turbine drives, pumps, centrifuges and other energy transmission gear. |

| Description | Densen YWINized mechanical gears equipment box cnc equipment for YWIN machinery products areas |

| Type | Cast Metal Spur Gear |

| Application | YWIN Resource Products,Agricultural YWINry,Chemical YWIN,Mining Products,and so forth |

| Processing | Open up Die Forging |

| Material | Carbon steel stainless metal (304/316/304L)Alloy Steel |

| Weight Ranges | 1-50000kg |

| Tolernace | Managed by GB/T 15826 |

| Design Assist | Pro-E, UG,SolidWorks,AutoCad, PDF |

| Top quality Management | Content, Dimension,Performance,inside of flaws,Balance examination |

| YWIN | ASTM,DIN,JIS,ISO,GB expectations |

Declaration:

Products demonstrated herein are manufactured to the demands of certain clients and are illustrative of the sorts of production capabilities available inside of Densen group of organizations.

Our coverage is that none of these goods will be bought to third events with no prepared consent of the buyers to whom the tooling, design and style and specs belong.

. YWINed provider of metal, iron & non-ferrous elements

2. Comprehensive documented top quality software in area.

3. YWINs, forgings, stampings, machining, welding & fabrication providers.

four. 9 related factories, in excess of 50 joint-undertaking sub-contractors.

5. twenty five+ years of manufacturing ordeals, ten+ years of exporting knowledge

six. one hundred% of products offered to abroad customers.

7. fifty% of buyer foundation is forturne 500 businesses.

Welding & Fabrication Services:

Welding Frabrication is the fabrication procedure of metal structures by reducing, bending, then assembling the components together by means of welding

New Densen offers manual arc welding ,laser welding and robot welding and many others. UT, MPT,RT,PT all are offered used for inspection, WPS &PQR (Welding Method Specification& Procedure Qualification Documents) prior to production is accessible under clients’ prerequisite.

Stamping Services:

Stamping (also acknowledged as punching) is the procedure of placing flat sheet metallic in possibly blank or coil form into a stamping press where a instrument and die surface kinds the metal into a net shape.

New Densen-XBL has much more than sixty sets stamping equipments, is the created provider for a number of famous bands automotive firms, has the complete ability to supply entire processes from blanking, stamping, welding, to electrostatic spraying for worldwide clients.

Forging Support:

Forging is a manufacturing process involving the shaping of metal using localized compressive forces. New Densen gives open die forging, shut die forging and ring forging services. Substance can be metal, iron and non-ferrous. Material can be managed contain steel, iron, non-ferrous. Single part bodyweight variety is from 0.1Kg to 50,000Kgs.

Machining Service:

Machining is any of different processes in which a piece of raw content is minimize into a sought after final shape and measurement by a controlled content-elimination procedure.

New Densen-XBL has more than 60 sets precision equipment incl. CNC center, boring, milling, lathing, and so on., and a lot more than three hundred inspection instruments incl. three sets CMM with grade μm. Recurring tolerance can be taken care of as .02mm. In the meantime awarded by certificates ISO9001-2008 ISO/TS16949. New Densen-XBL specialised in large precise machining for tiny-center-big steel parts.

third Party Inspection:

New Densen worked as 3rd social gathering inspection heart in addition to its sister factories or sub-contractors’ self inspection, Delivers method inspection, random inspection and before delivedry inspection services for material, mechanical, inside of flaws, dimentional, stress, load, harmony, surface therapy, visual inspection and check. Weekly undertaking comply with-up report with each other with pictures and videos, entire high quality inspection documentation offered.

New Densen also made as 3rd get together inspection agent for a number of consumers when their products created by other suppliers.

Two types of spiral bevel gears:left hand and right hand:

Characteristics:

- Material: carbon steel such as C45, 20CrMnTi, 40Cr, 42CrMo or stainless steel or copper or nylon and so on

- Heat Treatment: Hardening and Tempering, High Frequency Quenching, Carburizing Quenching and so on.

- YWIN: European or American standard

- Product: M0.5,M1,M1.five,M1.7,M2,M2.five,M3,M4,M5,M6 and so on

- Export Area: Europe and America

- OEM service: make based on your special sample or drawing and meet your need for high precision on teeth of gear

Quality control

» Serious raw material inspection

» Strict control over the entire manufacturing process

» Sampling of all the products after final inspection before shipment

» Quality trace after delivery

| Name | Gears |

| Content | Stainless, steel,iron,brass, aluminum alloy,carbon steel, alloy steel,magnesium alloy, red brass,plastic or adhere to your samples & drawings on supplies. |

| Tolerance | ± .03% |

| Inspection | 100% inspection prior to cargo. |

| Approach | PM/MIM/CNC/DIE-CASTING/STAMPING/HOBBING |

| Surface treatment | E-coating,electroplating and black oxygen, anodizing,polish,sandblasting,heat treatment ,Nickel plating Zinc plating, Chrome plating, Oxidation. Anodization etc |

| Software | automobile,lock program,electrical power resource,electric powered equipment,interaction appliance,household equipment,healthcare products,enjoyment systems or other equipment |

Firm introduction

YWIN Evon Engineering CO.,LTD is a manufacture of bearings, worm drivers, slewing bearings, gears, shaft and engineering parts. EVON bearings, worm drivers, slewing bearings, gears, shafts show every working day to be important structural and link components, they can be widely utilised in the lifting&transport machinery, mining machinery, construction equipment, port hoisting machinery, port oil transfer tools, onshore and offshore crane, excavator, concrete machine, paper device, plastic and rubber device, weave equipment, cement plant, steel plant, electric powered electrical power plant, wind power generator, other construction and sector equipment or tools and other huge rotary gadgets.

The goods produced by EVON Engineering Co are largely exported to the countries of the European Union, Usa, the Middle East, the South American, the Africa, Austrilian and Asia places and the Russian Federation, in the process of cooperation with our clients, we have created it a principle to create a lasting and satisfying partnership with our buyers by providing productive services with the best high quality and reducing the creation expense.

Aiming for steady motivation to the good quality of products and client service, Evon Engineering attaches wonderful value to research and improvement to make sure better product quality and provider from its establishment. The good quality of EVON merchandise are primarily based on the excellent expert and specialized amount of constructors and professionals, extremely experienced operators, ordeals creation employees.

The company title: Montreal Evon Engineering Co.,ltd

Address: No 3 Lianmeng Road, Jianxi Spot, YWIN City, Quebec Province, China

Tel: -379-64516701

Fax -379-64516702

Website: