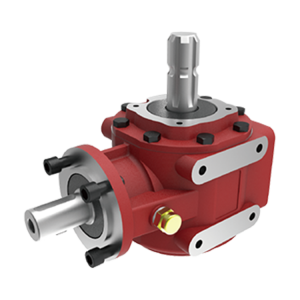

Product Description

Description: #eastarsmallenginerepair

Idler Pulley for Cub Cadet RZT50 LT1045 756- 0571 9 956- 0571 9 756- 0571 9B 956- 0571 9

· Replaces OEM Part # 956- 0571 9 753-5711 756- 0571 9 756 0571 9C

· Fits for Cub Cadet Part # 753-5711, 756- 0571 9B, 756- 0571 9C, 956- 0571 9, 956- 0571 9C,GTX1054, GTX2154LE, LGT1050, LGT1054, LGTX1050, LGTX1054, CC760, CC760ES, i1042, i1050, GT1054, GT2544, GT2550, GT2554, RZT-L50, RZT-L54, RZT-S42, RZT-S46, RZT-S50, RZT-S54, SLTX1550, SLTX1054, LT1040, LTX1040, LTX1042, LTX1050, RZT42, RZT50, RZT54, RZT-L42, RZT-L 46

· Fits for Troy Bilt Part # GT50, GT54, RZT 42, RZT 50, TB42, TB2142, TB2246, TB2450, Pony, Bronco, Super Bronco, Horse, Big Red Horse, Range Rider, Mustang, Mustang XP, Colt XP

| Replaces OEM Part # 956- 0571 9 753-5711 756- 0571 9 756 0571 9C | ||

| Fits for Cub Cadet Part # | 75 | 753-5711, 756- 0571 9B, 756- 0571 9C |

| 956 | 956- 0571 9, 956- 0571 9C | |

| GTX | GTX1054, GTX2154LE | |

| LGT | LGT1050, LGT1054,LGTX1050, LGTX1054 | |

| CC | CC760, CC760ES | |

| i | i1042, i1050 | |

| GT | GT1054, GT2544, GT2550, GT2554 | |

| RZT | RZT-L50, RZT-L54, RZT-S42, RZT-S46, RZT-S50,RZT-S54 | |

| SLTX | 1550, SLTX1054 | |

| LT | LT1040, LTX1040, LTX1042, LTX1050 | |

| RZT | RZT42, RZT50, RZT54, RZT-L42, RZT-L 46 | |

| ID | 3/8″ |

| OD | 4-7/8″ |

| FLAT OD | 4-1/4″ |

| Flat Width | 3/4″ |

| Overall Width | 1-1/8″ |

| OFFSET | 1/16″ |

| Material | Metal |

| Certification: | CE, ISO |

|---|---|

| Pulley Sizes: | Type A |

| Manufacturing Process: | Forging |

| Material: | Carbon Steel |

| Surface Treatment: | Electroplating |

| Application: | Chemical Industry, Grain Transport, Mining Transport, Power Plant, Outdoor Power |

| Samples: |

US$ 19.99/Set

1 Set(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do pulleys function in various types of vehicles and machinery?

Pulleys play crucial roles in numerous types of vehicles and machinery, enabling the transmission of power, control of mechanical systems, and efficient operation. Here’s how pulleys function in various applications:

1. Automotive Engines: In vehicles, pulleys are commonly used in the engine’s accessory drive system. The crankshaft pulley, also known as the harmonic balancer, is connected to the engine’s crankshaft and drives various accessories such as the alternator, power steering pump, and air conditioning compressor. The pulleys enable the transfer of rotational power from the engine to these accessories, allowing them to perform their respective functions.

2. Belt-Driven Systems: Pulleys are extensively used in belt-driven systems across various machinery and equipment. These systems utilize belts, such as V-belts or timing belts, which wrap around pulleys to transfer power. Examples include conveyor systems, industrial machinery, agricultural equipment, and HVAC systems. The pulleys provide the necessary grip and tension to ensure efficient power transmission and drive system operation.

3. Cranes and Hoists: Pulleys are integral components of cranes and hoists, enabling the lifting and movement of heavy loads. Multiple pulleys, often arranged in a block and tackle configuration, are used to create mechanical advantage, reducing the effort required to lift the load. By distributing the load’s weight over multiple strands of rope or cable, pulleys allow for controlled lifting and precise positioning of objects.

4. Construction Equipment: Pulleys are found in various types of construction machinery. For example, in excavators and cranes, pulleys are used in the wire rope systems for lifting and lowering the boom, bucket, or other attachments. Pulleys help in managing the forces involved in these operations, providing smooth and controlled movement.

5. Elevators: Pulleys are essential components in elevator systems. Elevator cars are suspended by steel cables that run over pulleys. These pulleys are connected to an electric motor through a system of gears and sheaves. As the motor rotates the pulleys, the elevator car moves up or down. Pulleys in elevator systems help in efficiently transferring power and maintaining the stability and safety of vertical transportation.

6. Exercise Equipment: Pulleys are widely used in exercise machines and gym equipment to provide resistance and enable adjustable resistance levels. By incorporating pulley systems with different configurations and cable arrangements, exercise equipment can offer a variety of exercises targeting specific muscle groups.

7. Marine Applications: Pulleys are utilized in various marine applications, such as sailboats and winches. Pulleys help in controlling the movement and tension of ropes and cables, enabling sail adjustments, mast raising and lowering, and other rigging operations.

8. Garage Doors: Pulleys are employed in garage door mechanisms to facilitate the smooth opening and closing of the doors. They are used in conjunction with cables or belts, allowing for the transfer of force from the door opener to the door itself.

These examples demonstrate the versatility and importance of pulleys in a wide range of vehicles and machinery. By utilizing pulleys, these systems can achieve efficient power transmission, mechanical advantage, controlled movement, and improved functionality.

How do pulleys contribute to the functioning of bicycles and motorcycles?

Pulleys play important roles in the functioning of both bicycles and motorcycles, aiding in power transmission, speed control, and overall mechanical efficiency. Here’s how pulleys contribute to the operation of these vehicles:

1. Bicycles:

– Derailleur System: In most modern bicycles, pulleys are used in the derailleur system. The derailleur is responsible for shifting the bicycle chain between different gears on the front and rear sprockets. Pulleys, often referred to as jockey wheels, are positioned in the derailleur to guide and tension the chain as it moves between gears. They ensure smooth and precise shifting, allowing the rider to adapt to various terrains and maintain an optimal pedaling cadence.

– Belt Drive Systems: Some bicycles use a belt drive instead of a traditional chain drive. Belt drives employ a pulley system that consists of a front pulley attached to the pedal crank and a rear pulley attached to the rear wheel hub. The belt is wrapped around these pulleys, transferring power from the rider’s pedaling motion to propel the bicycle forward. Pulleys in belt drive systems enable efficient power transfer, reduce maintenance needs, and provide a quieter and cleaner alternative to chain drives.

2. Motorcycles:

– Clutch System: Pulleys, known as clutch pulleys, are utilized in motorcycle clutch systems. The clutch connects the engine to the transmission and allows the rider to engage or disengage power transmission to the rear wheel. When the clutch lever is pulled, the clutch pulley separates the engine’s rotational motion from the transmission, disengaging power transfer. Releasing the clutch lever brings the pulley back into contact, engaging power transmission and enabling the motorcycle to move.

– Variable Transmission Systems: Some motorcycles employ pulleys in variable transmission systems, such as continuously variable transmissions (CVT). CVTs use a pair of pulleys connected by a belt or chain. By changing the diameter of the pulleys, the CVT adjusts the gear ratio continuously, providing seamless and efficient power delivery across a wide range of speeds. Pulleys in variable transmission systems contribute to smooth acceleration, improved fuel efficiency, and enhanced riding comfort.

– Drive Belt Systems: Pulleys are also utilized in motorcycles equipped with belt drive systems. Similar to bicycles, these systems consist of a front pulley connected to the engine’s crankshaft and a rear pulley connected to the rear wheel. The belt runs around these pulleys, transferring power from the engine to the rear wheel. Belt drive systems offer advantages such as reduced maintenance, quieter operation, and smoother power delivery compared to traditional chain drives.

Overall, pulleys are integral components in bicycles and motorcycles, contributing to smooth gear shifting, efficient power transmission, and improved overall performance. Whether in derailleur systems, belt drive systems, clutch systems, or variable transmission systems, pulleys play a vital role in enhancing the functionality and ride experience of these vehicles.

Can you explain the basic principles of pulley mechanics?

Pulley mechanics are based on a few fundamental principles that govern the operation of pulley systems. Here’s an explanation of the basic principles:

1. Mechanical Advantage: The primary principle of pulley mechanics is mechanical advantage. A pulley system allows for the multiplication of force applied to the rope or belt. By distributing the force over multiple segments of the rope or belt, the load becomes easier to lift or move. The mechanical advantage gained depends on the number of pulleys used in the system. The more pulleys in the system, the greater the mechanical advantage.

2. Force Transmission: When a force is applied to one end of the rope or belt, it creates tension that causes the pulley to rotate. As the pulley turns, the force is transmitted to the load attached to the other end of the rope or belt. This force transmission allows for the movement and manipulation of objects in pulley systems.

3. Directional Change: One of the key principles of pulley mechanics is directional change. A pulley system enables the operator to change the direction of the applied force. By redirecting the force along a different path, a pulley system allows for force to be exerted from a more convenient or advantageous position. This directional change is particularly useful in situations where the force needs to be applied vertically, horizontally, or at an angle.

4. Conservation of Energy: Pulley mechanics also adhere to the principle of conservation of energy. The work done on the load by the applied force is equal to the work done against the load’s weight. Through the pulley system, the input force is transformed into an output force that moves or lifts the load. The energy input and output remain the same, but the pulley system allows for the distribution and transformation of forces to achieve the desired mechanical advantage.

5. Speed and Torque Conversion: Pulleys can also be used to convert speed and torque in mechanical systems. By varying the size of the pulleys or using pulleys of different diameters, the rotational speed and torque can be adjusted according to the requirements of the system. This speed and torque conversion allows for the optimization of power transmission and the matching of different rotational speeds between input and output components.

6. Multiple Pulley Systems: Pulleys can be combined in systems to achieve increased mechanical advantage or to create complex motion patterns. In systems with multiple pulleys, such as block and tackle arrangements, the load is distributed over several segments of rope or belt, further reducing the effort required to lift heavy objects. These systems are often used in cranes, elevators, and other applications where heavy lifting is necessary.

These basic principles of pulley mechanics form the foundation for the understanding and application of pulleys in mechanical systems. By harnessing mechanical advantage, force transmission, directional change, conservation of energy, and speed/torque conversion, pulley systems provide a versatile means of lifting, moving, and manipulating loads in various applications.

editor by CX

2023-12-15