Product Description

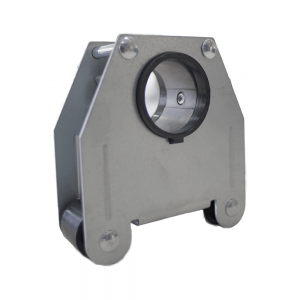

Product Title: Forklift gearbox transmission manual transmission forklift parts

Product Model: 14432-50001 Forklift gear

| Item | Description |

| Product Name | Forklift gear |

| P/N | 14432-50001 |

| Applied Model | Hehang |

| Net Weight (kg) | 168 |

| Gross Weight (kg) | 181 |

| Qty per Carton | 1 |

| Carton Size (cm) | 104*58*59 |

Forklift Mechanical Gearbox

The forklift gearbox transfers the output power of the forklift engine to the forklift driving axle through a mechanical transmission box. The function of the forklift mechanical gearbox is to change the torque and speed of the engine to meet the requirements of the driving and traction characteristics of the vehicle under various working conditions.

Classification Of Forklift Gearbox

1. According to power form: internal combustion power transmission, electric power transmission;

2. According to engine form: gasoline power transmission, diesel power transmission, liquefied gas power transmission;

3. According to the structure: mechanical transmission, hydraulic transmission, static pressure transmission.

| Material: | Aluminum Alloy |

|---|---|

| Surface Treatment: | Polishing |

| Customized: | Non-Customized |

| Standard: | Standard |

| Condition: | New |

| Feature: | Cost-Effective OEM Forklift Parts |

| Samples: |

US$ 534.9/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Steps to Replace a Faulty Gearbox in an Automobile

Replacing a faulty gearbox in an automobile is a complex task that requires proper tools, skills, and safety precautions. Here are the general steps involved in the process:

- Prepare the Vehicle: Park the vehicle on a flat surface and engage the parking brake. Disconnect the battery to ensure safety during the procedure.

- Drain Fluids: Drain the transmission fluid from the old gearbox into a suitable container.

- Disconnect Components: Remove any components obstructing access to the gearbox, such as the driveshaft, exhaust system, and linkage.

- Suspend the Engine: If necessary, use an engine hoist or support to suspend the engine safely.

- Support the Gearbox: Use a transmission jack to support the weight of the gearbox.

- Remove Gearbox: Detach the gearbox from the engine by removing bolts and disconnecting the clutch or torque converter.

- Install New Gearbox: Position the new gearbox onto the engine and secure it in place with bolts.

- Reconnect Components: Reattach the driveshaft, exhaust system, and linkage that were disconnected earlier.

- Refill Fluids: Fill the new gearbox with the appropriate transmission fluid according to the manufacturer’s specifications.

- Lower Engine: Carefully lower the engine back into its original position if it was suspended.

- Test and Adjust: Start the vehicle and test the new gearbox for proper operation. Check for any leaks, unusual noises, or gear shifting issues.

- Final Check: Double-check all connections and ensure that all components are properly secured.

- Dispose of Old Fluid: Dispose of the old transmission fluid safely and responsibly.

- Dispose of Old Gearbox: Properly dispose of the old gearbox according to local regulations.

It’s important to note that gearbox replacement can vary significantly depending on the vehicle’s make and model. It’s recommended to consult the vehicle’s service manual or seek professional assistance if you’re not experienced in automotive repair.

editor by CX 2023-12-12