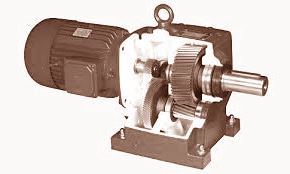

Our main merchandise, steel gearboxes ,gear systems for motors through powder metallurgy processing.

We specialize in developing and manufacturing highly engineered, custom made equipment parts , gearbox , factors and assemblies. Our expert personnel are geared towards supplying clients with substantial top quality merchandise and exceptional services .

In a easy planetary gearbox setup, enter power turns the sun equipment at higher speed. The planets, spaced around the central axis of rotation, mesh with the sunlight as effectively as the set ring gear, so they are compelled to orbit as they roll. All the planets are mounted to a single rotating member, named provider. As the earth provider turns, it provides minimal-pace, large-torque output. The Solar Gear Gets The Input Even though The three Planet Gears Give The Ouput By means of A Earth Carrier .

YWIN ratio 3 :one , :one , fifty:one , 100:one,five hundred:1 and so on.

YWINized metallic components specification

| Item kind | YWIN metallic gearbox ,planetary gears program , pace reducer , motor gears , custom motor gearbox , pace transmission |

| Materials | metallic : forged Iron , stainless steel |

| Method | Powder metallurgy , steel injection molding , cnc machining |

| Therapy | plating ,sand blasting , PVD , coating |

| Tolerance | ±0.three% |

| Drawing format | DWG ,IGS , STP |

| Supply time | ten days for mass production |

Our gearbox,Light-weight weight,tiny dimension, substantial carrying ability, extended service existence .Clean operation, reduced sounds, large output torque, massive speed ratio, high efficiency, electricity diversion, and multi-tooth meshing by powder metallurgy procedure .

Powder metallurgy (PM) is a steel areas / components fabrication way and made from metal powders substance . The approach of powder metallurgy (PM) is blending good powder supplies , push them into a preferred shape or sort compacting , and heating the compressed material in a managed ambiance to bond the material sintering .PM process can stay away from , or significantly minimize the require to use steel removal processes,therefore dramatically minimizing produce losses in manufacture and oftern ensuing in decrease fees .

The powder metallurgy (PM) consist a few actions : powder blending,compaction and sintering .Typical items consist of gears , structural metallic components , bushings employed for vehicles , appliances and powder equipments .

Advantages of powder metallurgy

Goods made by powder metallurgy (PM) generally do not want additional finishing , because makes very good area end.

Maintains close dimensional tolerances

Supplies resources which may possibly be heat treated for improved toughness or increased put on resistance .

There is considerably less wastage of uncooked material , can be extremely inexpensive for mass production .

Intricate shapes areas can be created . Provides managed porosity for self-lubrication or filtration.

Suits to substantial quantity areas productions requirements .

YWIN metal parts

Workshop