C Purlin Roll Forming YWINry Manufacture

Profile drawing:

| A | B | C |

| a hundred | 50 | 15 |

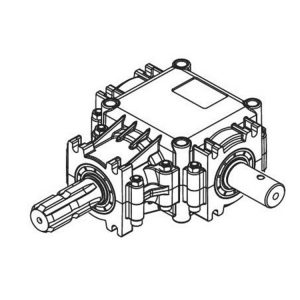

I: Composition of machine

Roll forming primary machine——————unit

Handbook Uncoiler——————————-device

Control panel———————————-unit

YWIN station——————————unit

Manual out table——————————device

Spare resources————————————unit

II: Details of every single composition

A: Roll forming main equipment

one: Coil width: based on profile drawing

two: Functioning velocity: 12m_15m/min (not contain reducing)

3: Roll station:

Roll forming: 14stations )ASTM52100, polished and coated with chrome HRC58-62)

Leveling station: seven rollers ( up a few rollers, down 4 rollers)

Diameter of roller: 76mm

Material of roller: ASTM1045, polished and coated with chrome HRC58-sixty two

Revising station: one station aterial(STM52100 polished and coated with chrome HRC58-62)

four: Substance of principal shaft: ASTM1045 diameter roller 6mm

five: Principal electricity: 15kw DC motor

6: Forming thickness: 2mm

7: Transmission: By one line chain one.5inch

eight: YWIN adopt new stations to make device more powerful

nine: Punching:

Foundation on consumer request this machine need to have one particular set of punching program

YWIN adopt hydraulic following reducing

Punching mould: Cr12 HREC58-sixty two

Punching distance is adjustable by personal computer

10: Dimensions of device: About 10m*one.5m*1.2m (L x W x H) require one 40GP container

eleven: Shade: Blue (it is also can modify base on client request)

12: Chopping:

(one)YWIN adopt hydraulic following cutting

(2)Chopping right after forming: Lower the sheet soon after roll forming to required size

(3)Cutting motion: The main device routinely stops and the chopping will take place. Right after the reducing, the primary machine will routinely begin.

(4)Substance of blade: D2with warmth therapy total three cutters

(five)Duration measuring: Automatic length measuring

(six)Tolerance of length: 3m +/- 1.5mm

thirteen: Foundation on buyer ask for, this machine need to be contain cooling method for roll forming parts. So in very hot air temperature this sort of cooling program can safeguard the rollers.

Drinking water pump: 1.5KW

Spout: About 5-6 parts (it is base on last layout)

H2o box which can make drinking water can circulate functioning: One particular piece

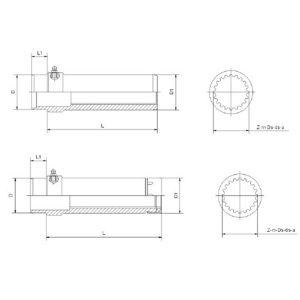

B. Uncoiler

Dimensions: 1700mm*1000mm*800mm

Width of feeding: 600mm

Functionality: five Ton

Sure of broaden &fight: 450mm_550mm

Method of increase &struggle: Internal grow &struggle by handbook

Way of feeding: Handbook

C: Manage panel Panasonic

(1)Voltage, Frequency, Phase: 380 V, fifty Hz, 3Phase

(2)Computerized size measurement:

(3)Automatic amount measurement

(4)Laptop utilized to management length & amount. YWIN will automatically reduce to length and cease when essential quantity is attained

(5)Length inaccuracy can be amended effortlessly.

(six). Manage panel: Button-variety switch and touch display

(seven)Unit of duration: Millimeter (switched on the manage panel)

D: YWIN station

one: YWIN station electrical power: five.5kw

two: YWIN force: 20Mpa

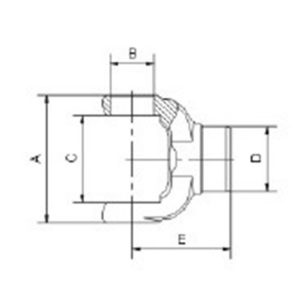

E: Handbook out table:

(1)Jointed by 60mm*40mm tube

(two)Measurement: one.0m long*.8mwide*.six-1mhigh

(3)1 out desk with two assistance roller