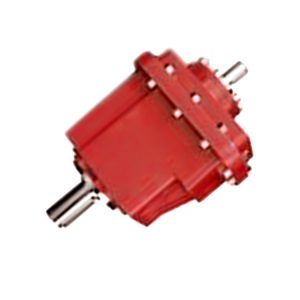

Description

1、 Output Hubs

Standard or alternative hubs with metric bores are available to suit inter national shaft diameters.

2 Precision High Quality Gearing

Computer Designed Helical Gear. Strong Alloy Materials for High Load Capacity, Case Carburized for long life, Ground Profile (some intermediate pinions are shaved), Crown tooth Profile, In Conformance with ISO 1328-1997, 98% Efficiency for per Stage, Smooth Quiet Operation with Teeth in Mesh.

3、Maximum Capacity Housing Design

Close Grain Cast Iron Construction, Excellent Vibration Dampening & shock Resistance features, Precision Bored and Dowelled to Ensu『e Accurate In一line Assembly.

4、Strong Alloy Steel Shafts

Strong Alloy Steel, Hardened, Ground on journals, Gear Seatings and Extensions, for Maximum Load and Maximum Torsional Loads, Generous Sizes Shaft Keys for Shock Loading and Conform to ISO Standards.

5、Additional Case Lugs(Except H and J Gear Case)

Eliminates the Need for Critical Tightening of Torque arm Bolts, Controls Position of Standard Torque Arm Mounting within Recommended limits.

6、Backstops

Alternative Parts, Anti-run Back Device, Are Available on all 13:1 and 20:1 Ratio units and do not recommend for 5:1 Units.

7、 Bearing and Oil seals

Bearing are Adequately Proportioned and Conform to ISO dimension plan, Readily Available World-wide, Oil seals are Double Lipped Garter Spring Type, Ensuring Effective Oil Sealing.

8、 Rubberised End Caps

Self Sealing Intermediate Cover Plates, to Standard ISO Housing Dimensions.

9、 Torque Arm Assembly

For Easy Adjustment of the Belt