Product Description

Product Description

PM/SCHWING /ZOOMLION Pump Cylinder

| Putzmeister | |||

| Outer Diameter(mm) | Inner Diameter(mm) | length(mm) | Travel(mm) |

| 305 | 280 | 2355 | 2200 |

| 278 | 250 | 2710 | 2500 |

| 278 | 250 | 2310 | 2100 |

| 254 | 230 | 2320 | 2100 |

| 254 | 230 | 1600 | 1400 |

| 219 | 200 | 2305 | 2100 |

| 219 | 200 | 1585 | 1400 |

| 203 | 180 | 2305 | 2100 |

| Schwing | |||

| Outer Diameter(mm) | Inner Diameter(mm) | length(mm) | Travel(mm) |

| 270 | 250 | 2635 | 2500 |

| 270 | 250 | 2135 | 2000 |

| 251 | 230 | 2125 | 2000 |

| 251 | 230 | 2133 | 2000 |

| 253 | 230 | 1175 | 1000 |

| 219 | 200 | 2125 | 2000 |

| 219 | 200 | 1775 | 1600 |

| 210 | 180 | 2125 | 2000 |

| 203 | 180 | 2125 | 2000 |

| 202 | 180 | 1775 | 1600 |

| 200 | 180 | 1520 | 1400 |

| 196 | 180 | 1320 | 1200 |

| 200 | 180 | 1175 | 1000 |

| Outer Diameter(mm) | Inner Diameter(mm) | length(mm) | Travel(mm) |

| 280 | 260 | 2345 | 2200 |

| 280 | 260 | 2245 | 2100 |

| 280 | 260 | 2145 | 2000 |

| 280 | 260 | 2045 | 1900 |

| 258 | 230 | 2146 | 2000 |

| 258 | 230 | 1946 | 1800 |

| 258 | 230 | 1746 | 1600 |

| 226 | 200 | 1946 | 1800 |

| 226 | 200 | 1746 | 1600 |

| 226 | 200 | 1546 | 1400 |

| Zoomlion | |||

| Outer Diameter(mm) | Inner Diameter(mm) | length(mm) | Travel(mm) |

| 280 | 260 | 2250 | 2100 |

| 250 | 230 | 2250 | 2100 |

| 258 | 230 | 1800 | 1600 |

| 219 | 200 | 1960 | 1800 |

| 219 | 200 | 1800 | 1600 |

| 219 | 200 | 1587 | 1400 |

FAQ:

1.HOW LONG CAN I GET THE FEEDBACKS AFTER WE SENT THE INQUIRY?

We will reply you within 12 hours in working day.

2.ARE YOU A DIRECT MANUFACTURER OR TRADING COMPANY?

We are MANUFACTURER

3.WHAT PRODUCTS CAN YOU OFFER?

We focus on concrete pump spare parts.

4.WHAT APPLICATIONS DO YOUR PRODUCTS RELATE TO?

Our products cover a wide range of industries including concrete pump & automobile & truck, construction machinery, mixer truck, building, hardware and so on.

5.CAN YOU DO CUSTOMIZED PRODUCTS?

Yes,we are mainly doing customized products according to the customers’ drawings or samples.

6.DO YOU HAVE SOME STHangZhouRD PARTS?

Yes,We are manily in concrete pump OEM standard parts,also can call it as construction machinery.

7.HOW TO GUARANTEE THE QUALITY OF YOUR GOODS?

Firstly,we will do the inspection after every process.For the finished products,we will do 100% inspection according to the customers’ requirements and the international standard.

8.WHAT’S THE PAYMENT TERM?

When we quote for you,we will confirm with you the way of transaction,FOB,CIF,CNF,etc.

For mass production goods, you need to pay 50% deposit before producing and50% balance after we packed but before shipping .The most common way is by T/T. L/C is also acceptable.

9.HOW TO DELIVER THE GOODS TO US?

Usually we will ship the goods to you by sea,we also could sent out by air ,both are very convenient .

10.WHERE ARE YOUR PRODUCTS MAINLY EXPORTED TO?

Our products are mainly exported to over 30 countries such as Mexico,Malaysia,Japan,Chile,Jordan,Iran,Turkey,Lebanon,Thailand and etc.

| After-sales Service: | Available |

|---|---|

| Warranty: | 1-Year |

| Type: | Concrete Pump |

| Samples: |

US$ 500/Piece

1 Piece(Min.Order) | Order Sample As requirements

|

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can hydraulic cylinders be adapted for specialized applications like material handling?

Yes, hydraulic cylinders can be effectively adapted for specialized applications such as material handling. The versatility, power, and precise control offered by hydraulic cylinders make them well-suited for a wide range of material handling tasks. Hydraulic systems, including cylinders, are commonly used in industrial settings to lift, position, push, pull, and manipulate various types of materials. Here’s a detailed explanation of how hydraulic cylinders can be adapted for specialized material handling applications:

1. Lifting and Lowering:

– Hydraulic cylinders are commonly used for lifting and lowering heavy loads in material handling applications. By utilizing the force generated by hydraulic pressure, cylinders can provide the necessary power to lift and hold loads at different elevations. The precise control offered by hydraulic systems allows for accurate positioning of materials, ensuring efficient and safe lifting operations.

2. Pushing and Pulling:

– Hydraulic cylinders are capable of generating substantial pushing and pulling forces, making them ideal for applications that involve moving or manipulating materials. They can be used to push or pull heavy objects, control the movement of conveyors or rollers, or engage mechanisms for material transfer. The ability to exert high forces with precise control enables hydraulic cylinders to efficiently handle a variety of material handling tasks.

3. Tilting and Rotating:

– Hydraulic cylinders can be adapted to provide tilting and rotating functions in material handling equipment. By integrating cylinders into the design, equipment such as forklifts, cranes, or material handling arms can tilt or rotate to facilitate material placement or maneuvering. Hydraulic cylinders offer the required force and control to achieve smooth and controlled tilting or rotating motions, enhancing operational efficiency in material handling processes.

4. Gripping and Clamping:

– Hydraulic cylinders can be utilized to provide gripping and clamping functions for secure material handling. By incorporating specialized gripping or clamping mechanisms with hydraulic actuation, materials of various shapes and sizes can be securely held or clamped during transportation or processing. Hydraulic cylinders enable precise and adjustable gripping or clamping forces, ensuring the safe and reliable handling of materials.

5. Material Compaction and Forming:

– Hydraulic cylinders can be adapted for material compaction and forming applications. For example, in the production of bricks, hydraulic cylinders are used to apply high pressure and force to compact the raw materials into desired shapes. Similarly, in metal forming processes, hydraulic cylinders are employed to exert force on metal sheets or components, enabling precise shaping and forming operations.

6. Conveyor and Sorting Systems:

– Hydraulic cylinders can be integrated into conveyor and sorting systems to facilitate material movement and sorting. By incorporating hydraulic actuators, conveyor belts or sorting mechanisms can be efficiently controlled for optimal material flow and distribution. Hydraulic cylinders provide the necessary force and control to handle varying load capacities and adjust the speed and position of material transfer, improving the overall efficiency of handling and sorting operations.

7. Customized Designs:

– Hydraulic cylinders can be customized and adapted to meet specific requirements of specialized material handling applications. Engineers can design cylinders with unique dimensions, stroke lengths, mounting options, and sealing arrangements to fit into equipment or systems with specific space limitations or operating conditions. Customized hydraulic cylinders ensure optimal performance and compatibility for specialized material handling tasks.

In summary, hydraulic cylinders can be effectively adapted for specialized material handling applications, offering the necessary force, control, and versatility required in various material handling tasks. Whether it involves lifting and lowering, pushing and pulling, tilting and rotating, gripping and clamping, material compaction and forming, or integration into conveyor and sorting systems, hydraulic cylinders provide reliable and efficient solutions. Their adaptability, precise control, and ability to handle heavy loads make hydraulic cylinders a valuable component in optimizing material handling processes across different industries.

Ensuring Controlled and Safe Force Application in Heavy Machinery with Hydraulic Cylinders

Hydraulic cylinders play a critical role in heavy machinery by ensuring controlled and safe force application. The ability to exert and control high forces is essential for heavy machinery operations, such as lifting, pressing, pushing, or pulling heavy loads. Let’s explore how hydraulic cylinders ensure controlled and safe force application in heavy machinery:

- Force Control: Hydraulic cylinders provide precise force control capabilities. The hydraulic system’s pressure can be adjusted to regulate the force exerted by the cylinder. This control allows operators to apply the necessary force for a specific task while ensuring it remains within safe limits. By accurately controlling the force, hydraulic cylinders help prevent excessive force that could damage the machinery or compromise the safety of the operation.

- Load Balancing: In heavy machinery, multiple hydraulic cylinders are often used in conjunction to distribute and balance the applied force. By using multiple cylinders, the load can be evenly distributed across the machinery, minimizing stress concentrations and ensuring controlled force application. This load balancing approach enhances the stability and safety of the machinery, preventing uneven loading that could lead to structural issues or instability.

- Safety Valves: Hydraulic systems in heavy machinery are equipped with safety valves to protect against excessive force or overloading. Safety valves are designed to release hydraulic fluid from the cylinder when the force exceeds a predetermined threshold. This prevents the force from reaching dangerous levels, safeguarding the machinery and preventing potential accidents or damage. Safety valves provide an additional layer of safety and ensure controlled force application even in unexpected circumstances.

- Pressure Relief Systems: Hydraulic cylinders incorporate pressure relief systems to further enhance safety. These systems are designed to relieve excess pressure in the hydraulic system, which could occur due to factors such as thermal expansion or system malfunctions. By relieving excess pressure, the pressure relief systems prevent sudden and uncontrolled force surges, maintaining safe and controlled force application in heavy machinery.

- Structural Integrity: Hydraulic cylinders are designed to withstand the high forces and loads associated with heavy machinery applications. The cylinders are constructed using robust materials, such as high-strength steel, and undergo rigorous testing to ensure their structural integrity. This ensures that the cylinders can safely handle the forces applied during heavy machinery operations without experiencing failures or deformations that could compromise the safety and controlled force application.

In summary, hydraulic cylinders ensure controlled and safe force application in heavy machinery through force control, load balancing, safety valves, pressure relief systems, and robust structural design. These features and design considerations enable operators to exert the necessary force while maintaining safety and preventing excessive loads or force surges. By incorporating hydraulic cylinders into heavy machinery, manufacturers can achieve controlled force application, enhance operational safety, and protect the machinery from damage or failure.

How do hydraulic cylinders generate force and motion using hydraulic fluid?

Hydraulic cylinders generate force and motion by utilizing the principles of fluid mechanics, specifically Pascal’s law, in conjunction with the properties of hydraulic fluid. The process involves the conversion of hydraulic energy into mechanical force and linear motion. Here’s a detailed explanation of how hydraulic cylinders achieve this:

1. Pascal’s Law:

– Hydraulic cylinders operate based on Pascal’s law, which states that when pressure is applied to a fluid in a confined space, it is transmitted equally in all directions. In the context of hydraulic cylinders, this means that when hydraulic fluid is pressurized, the force is evenly distributed throughout the fluid and transmitted to all surfaces in contact with the fluid.

2. Hydraulic Fluid and Pressure:

– Hydraulic systems use a specialized fluid, typically hydraulic oil, as the working medium. This fluid is stored in a reservoir and circulated through the system by a hydraulic pump. The pump pressurizes the fluid, creating hydraulic pressure that can be controlled and directed to various components, including hydraulic cylinders.

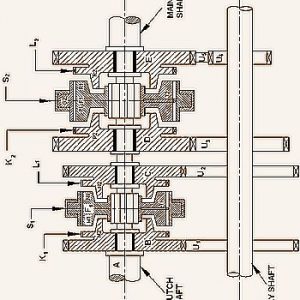

3. Cylinder Design and Components:

– Hydraulic cylinders consist of several key components, including a cylindrical barrel, a piston, a piston rod, and various seals. The barrel is a hollow tube that houses the piston and allows for fluid flow. The piston divides the cylinder into two chambers: the rod side and the cap side. The piston rod extends from the piston and provides a connection point for external loads. Seals are used to prevent fluid leakage and maintain hydraulic pressure within the cylinder.

4. Fluid Input and Motion:

– To generate force and motion, hydraulic fluid is directed into one side of the cylinder, creating pressure on the corresponding surface of the piston. This pressure is transmitted through the fluid to the other side of the piston.

5. Force Generation:

– The force generated by a hydraulic cylinder is a result of the pressure applied to a specific surface area of the piston. The force exerted by the hydraulic cylinder can be calculated using the formula: Force = Pressure × Area. The area is determined by the diameter of the piston or the piston rod, depending on which side of the cylinder the fluid is acting upon.

6. Linear Motion:

– As the pressurized hydraulic fluid acts on the piston, it generates a force that moves the piston in a linear direction within the cylinder. This linear motion is transferred to the piston rod, which extends or retracts accordingly. The piston rod can be connected to external components or machinery, allowing the generated force to perform various tasks, such as lifting, pushing, pulling, or controlling mechanisms.

7. Control and Regulation:

– The force and motion generated by hydraulic cylinders can be controlled and regulated by adjusting the flow of hydraulic fluid into the cylinder. By regulating the flow rate, pressure, and direction of the fluid, the speed, force, and direction of the cylinder’s movement can be precisely controlled. This control allows for accurate positioning, smooth operation, and synchronization of multiple cylinders in complex machinery.

8. Return and Recirculation of Fluid:

– After the hydraulic cylinder completes its stroke, the hydraulic fluid on the opposite side of the piston needs to be returned to the reservoir. This is typically achieved through hydraulic valves that control the flow direction, allowing the fluid to return and be recirculated in the system for further use.

In summary, hydraulic cylinders generate force and motion by utilizing the principles of Pascal’s law. Pressurized hydraulic fluid acts on the piston, creating force that moves the piston in a linear direction. This linear motion is transferred to the piston rod, allowing the generated force to perform various tasks. By controlling the flow of hydraulic fluid, the force and motion of hydraulic cylinders can be precisely regulated, contributing to their versatility and wide range of applications in machinery.

editor by CX 2023-12-03