Scraper Chain for Grain YWINs (Welded Steel Chain)

The welded metal chain is also known as scraper chain, and is commonly utilized through the grain processing sector. It is compatible with abrasive components, and mainly supports reduced speed load carrying. Additionally, it is able to work in serious environments with hefty dust and sturdy impacts.

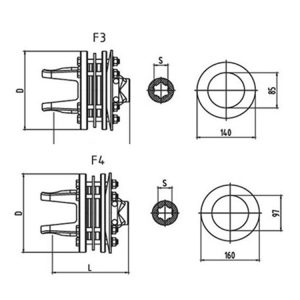

This variety of conveyor chain is composed of bended sidebars which are exactly the very same. The sidebars are related with each other right without having other varieties of website link plates. The chain link can be both odd or even amount. The sleeve and sidebars are welded collectively, which ensures easy but sturdy construction.

In buy to make scraper chains with enhanced top quality and prolonged provider lifestyle, we undertake computerized welding robots to weld the bushing and sidebar with each other. The precision gear ensures uniform and steady welding top quality. In the meantime, we conduct inspections according to the Good quality Management YWIN of worldwide major roller chain makers. Moreover, according to the proportion of five%, our welded metal chain merchandise undergo carry out harmful assessments to ensure approved welding high quality. Our patented substantial frequency induction heating treatment method for the pins provides larger energy even though bettering the donning resistance.

| Chain No. | Pitch P (mm) | Outer diameter of bushing d1 (mm) | Diameter of pin d2 (max) (mm) | Height of sidebar h2 (max) (mm) | Inner width among tiny ends b1 (mm) | Outer width between tiny ends b2 (mm) | Thickness of sidebar T (mm) | Dimension of scraper | Tensile strength Q (min) (KN) | |||

| L1 (mm) | L2 (mm) | L3 (mm) | D (mm) | |||||||||

| DC200-1 | seventy eight.1 | 26.97 | fourteen.35 | 31.8 | 38.1 | fifty seven.4 | 6 | 110 | 150 | 170 | 10 | 132 |

| DC250-1 | 78.1 | 26.ninety seven | 14.35 | 31.8 | 38.1 | 57.4 | six | a hundred thirty | a hundred and eighty | 220 | 10 | 132 |

| WH82 | 78.one | twenty five.four | fourteen.29 | 32 | 31.8 | 57 | 6.4 | a hundred and fifty five | 235 | 265 | fourteen | a hundred.1 |

| DC400.01 | seventy eight.1 | twenty five.4 | fourteen.29 | 32 | 31.8 | 57 | six.four | one hundred sixty | 320 | 350 | 14 | a hundred.1 |

| DC315.01 | 101.6 | 36.5 | 19.05 | 38.one | forty one.28 | sixty nine.nine | 9.5 | one hundred sixty five | 235 | 265 | 14 | 300 |

| DC320-1 | a hundred and one.6 | 31.75 | 19.05 | 38.one | 41.28 | 66.nine | eight | 150 | 190 | 270 | twelve | three hundred |

| DC40W.01 | one zero one.six | 36.5 | 19.05 | 38.one | 41.28 | 69.nine | nine.five | one hundred seventy | 280 | 310 | 14 | three hundred |

| DC400-1 | a hundred and one.6 | 31.75 | 19.05 | 38.1 | 41.28 | sixty nine.9 | 9.5 | one hundred seventy | 290 | 330 | twelve | 300 |

| DC500-1 | 153.sixty seven | forty four.forty five | 25.four | 50.8 | 59 | ninety one.2 | 10 | 230 | 370 | 430 | fourteen | 356 |

| DC500-one-A | 153.67 | forty four.forty five | twenty five.four | 50.8 | sixty six | ninety eight | 10 | 230 | 370 | 430 | 14 | 356 |

| DC500×254-one | 153.67 | 44.45 | twenty five.4 | 50.eight | fifty nine | 91.two | ten | 224 | 374 | 434 | 14 | 356 |

| WH132-498 | 153.67 | 44.45 | 25.05 | 50.eight | seventy six.2 | 111.eight | 12.7 | 201.4 | 441.4 | 498 | 13 | 378.1 |

| DC630-one | 153.sixty seven | forty four.forty five | twenty five.4 | fifty.8 | sixty six | ninety eight | 10 | 230 | five hundred | 560 | 14 | 356 |

| DC660×254-one | 153.sixty seven | forty four.forty five | twenty five.4 | fifty.8 | 66 | 102 | twelve | 224 | 534 | 594 | 14 | 511 |

| DC630×254-1 | 153.sixty seven | 44.45 | twenty five.4 | fifty.8 | sixty six | 102 | 12 | 224 | 504 | 564 | fourteen | 511 |

| DC800-1 | 153.sixty seven | forty four.forty five | twenty five.four | fifty.eight | 68 | 104 | 12 | 230 | 450/670 | 730 | 14 | 511 |

| DC800×356-one | 153.67 | 44.45 | 28.75 | sixty | 73 | 109 | twelve | 226 | 450/674 | 734 | 14 | 543 |

| DC1016-1 | 153.67 | forty four.forty five | 28.seventy five | 60 | 73 | 109 | twelve | 230 | 560/890 | 950 | fourteen | 543 |

| Chain No. | Pitch P (mm) | Outer diameter of bushing d1 (mm) | Diameter of pin d2 (max) (mm) | Top of sidebar h2 (max) (mm) | Inner width amongst tiny finishes b1 (mm) | Outer width between modest finishes b2 (mm) | Thickness of sidebar T (mm) | Dimension of scraper | Tensile energy Q (min) (KN) | |||

| L1 (mm) | L2 (mm) | L3 (mm) | D (mm) | |||||||||

| DC400×203-1 | 101.six | 31.75 | 19.05 | 38.one | forty one.28 | sixty nine.nine | nine.five | 154 | 294 | 334 | 12 | 300 |

| WH130×400 | 153.67 | forty four.forty five | twenty five.two | 50.8 | seventy six.two | 111.8 | 12.7 | 230 | 350 | four hundred | fourteen | 378.one |

| DC500×254 | 153.67 | forty four.45 | 25.4 | 50.8 | fifty nine | 91.two | ten | 224 | 374 | 434 | fourteen | 356 |

| DC630×254 | 153.67 | 44.45 | twenty five.4 | fifty.eight | sixty six | 102 | twelve | 224 | 504 | 564 | 14 | 511 |

| DC660×254 | 153.sixty seven | 44.forty five | twenty five.four | fifty.8 | 66 | 102 | 12 | 224 | 534 | 594 | thirteen | 511 |

| DC762×254 | 153.67 | 44.forty five | 28.seventy five | fifty.8 | 73 | 109 | 12 | 226 | 636 | 696 | 14 | 543 |

| DC800×254 | 153.67 | forty four.45 | 28.75 | sixty | seventy three | 109 | twelve | 226 | 450/674 | 734 | 14 | 543 |

| DC1016-one | 153.67 | forty four.45 | 28.75 | 60 | 73 | 109 | 12 | 230 | 560/890 | 950 | 14 | 543 |

| Chain No. | Pitch P (mm) | Outer diameter of bushing d1 (mm) | Diameter of pin d2 (max) (mm) | Peak of sidebar h2 (max) (mm) | Inner width amongst small ends b1 (mm) | Outer width amongst small finishes b2 (mm) | Thickness of sidebar T (mm) | Dimension of scraper | Tensile strength Q (min) (KN) | |||

| L1 (mm) | L2 (mm) | L3 (mm) | D (mm) | |||||||||

| WH150 | 153.sixty seven | forty four.forty five | 28.57 | sixty three.five | 73 | 111.76 | twelve.seven | 163.four | 193.four | 240 | 18 | 542 |

For much more than 20 many years, we have centered on customized chains.

For a lot more than twenty a long time, We have carried out hundreds of different varieties of industrial chains.

So we have a prosperity of personalized chain expertise.

Right here are some of the varieties of the chains.