Brief introduction:

CL lengthy shaft submerged pump is deriving item of CLWII sequence,it was made to fulfill the unique specifications of long shaft submerged pump,like no stale cleanse h2o(for pump lubricating) at website,or only wants to pump clean water,and the cost issue.

Brief introduction:

CLWII long shaft sewage pump is an up to date product which was developed based mostly on the ongoing absorption of the YWINd systems of overseas as nicely as the self-innovation. The distinctive design philosophy and a long time expertise eliminated the troubles in the identical kind pumps,which are brief daily life of bearings,significant vibration,bending shaft,frequently upkeep…It is extensively used in the ferric oxide scale sewage and other sewages of steel rolling rotating stream well of steel companies.

Parameters:

- Flow rate:Q=17~3500 (m³/h)

- Total head:H=six.5~100 (m)

- Pace:n=980-1470rpm

- S.g.:γ ≤1.fifteen

- Temperature:T=~80ºC

- Pump diameter:eighty~600mm

Functions:

- Adopted YWINd structure and hydraulic models to enable long life operation of high efficiency and stability.

- Compact structure takes smaller space,which is benefit to the complete arrangement of steel rolling process.

- YWINized sectional length of pump shaft to meet different submerged depths.

- Guide bearing adopts the material of high-molecular polymer with water lubrication.

- Sectional combination structure enables the sectional maintenance to save the cost of operation.

- Especially suitable for pumping the ferric oxide scale sewage of steel industry.

Construction:

- Guide vane type submerged pump,impeller is immersed in the fluid,the guide vanes in the middle section pushing the fluid all the way up along the main shaft.

- The guide vanes can work in series,maximally 4 stages.

- Shafts are connected by a special method with high precision,therefore,the submerged depth is up to 10 m.

- The pump shafts are supported by guide bearingsthe fluid is separated with shafts by the guard plates.

- Vertical installation with horizontal pump outlet The rotary part is driven by the motor through the couplings.

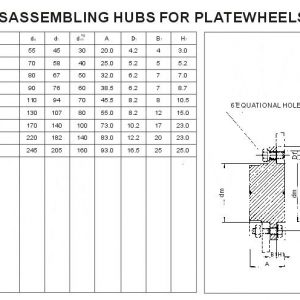

Structure drawing is as below

one.rolling bearing assembly 2.seal component 3.bracket 4.protective tube 5.connecting pipe 6.guide bearing bracket 7.joint assembly 8.guide bearing 9.lubricating pipe assembly 10.spatial guide vane 11.shaft 12.shaft sleeve 13.lower guide bearing 14.impller 15.pump cover 16.impeller nut 17.filter

Configuration:

Application:

- Suitable for pumping sewages with solids,like ferric oxide scale sewage,fluids with mud and sand,pulverized coal…

- Especially suitable for pumping the ferric oxide scale sewage of steel industry.

- Suitable to pump clean water or fluids have close characters with waterThe pumping temperature is below 80ºC, solid diameter below 10 mm, fluid density below 15%.