UMC® is the market leader in gearbox technologies. Above our forty 12 months history we have introduced several business modifying gearboxes such as the patented TNT gearbox, the 740, the 760, the 775 and much more. We proceed to outline and redefine market expectations for gearbox overall performance, top quality, functions and technologies. Our gearboxes are purpose developed to do the task. By no means above-engineered.

UMC® stands powering its products and is dedicated to producing the best items for a global industry.

740-U 50:one Ratio

Made for lengthier spans, bigger wheels, and heavier towers.

Functions and Positive aspects

- 2.twenty five inch output shaft

- fifty:1 equipment ratio

- Cartridge input and output seals

- More substantial enter bearings

- Input shaft guard

- Exterior seal protectors for enter and output seals

- Prime oil fill plug

- Common mounting sample

- Full cycle growth chamber with stainless steel go over

- Filled with intense strain worm equipment oil

- Metal output shaft and input shaft

- Tapered roller bearings

- Includes carriage bolts and nuts

- Twin finished enter shaft

740-UV 52:1 Ratio

Created for for a longer time spans, larger wheels and heavier towers the place an prolonged output shaft is essential.

This gearbox has all the same abilities, characteristics and advantages that the common 740 has with a number of tweaks. The output shaft is prolonged, the equipment ratio is 52:1 and the input shaft is manufactured of ductile iron with a 25° pressure angle enabling this gearbox to be used on heart pivot and lateral transfer/ linear methods that arrive regular with these specifications.

Features and Benefits

- two.25 inch extended output shaft

- fifty two:1 equipment ratio with 25° pressure angle

- Cartridge enter and output seals

- More substantial input bearings

- Input shaft guard

- Exterior seal protectors for enter and output seals

- Prime oil fill plug

- Universal mounting pattern

- Total cycle expansion chamber with stainless steel protect

- Filled with extreme strain worm gear oil

- Steel output shaft and ductile iron input shaft

- Tapered roller bearings

- Includes carriage bolts and nuts

- Twin finished input shaft

760-UV YWIN

Created for corner programs and lateral transfer carts where an extended output shaft is needed

Growers normally use UMC’s 760-UV gearbox for the most intense purposes in which an extended output shaft is necessary. The gearbox is developed for greater yearly several hours of procedure although managing the weighty loads knowledgeable on corner techniques and lateral move carts as effectively as the most excessive field problems exactly where wheel rutting is well known, soil is heavy, and tower weights are larger.

The UMC® 760-UV final generate gearbox is our premier and most sturdy gearbox with an extended output shaft. It characteristics a more substantial-diameter bull gear than the normal 740 sequence to handle 20% increased torque. It also functions a two.5″ output shaft to accommodate more overhung load. It is created for use on heart pivots, corners, lateral move/ linear irrigation programs and carts in which a fifty two:one equipment ratio and prolonged output shaft are common specs.

Characteristics and Benefits

- 2.5″ output shaft

- fifty two:1 equipment ratio with a 25° stress angle

- Exclusive twin input and output seal design

- twenty% far more torque potential than the normal 740

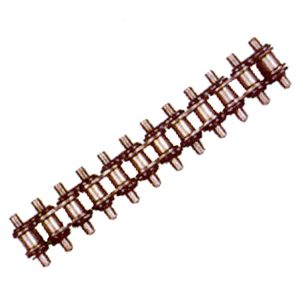

- Bronze gear optional

- More substantial input bearings

- Input shaft guard

- External seal protectors for enter and output seals

- 11-Bolt mounting pattern

- Entire cycle growth chamber with aluminum cover

- Loaded with intense stress worm gear oil

- Metal output shaft and ductile iron input shaft

- Tapered roller bearings

- Consists of carriage bolts and nuts

- Twin finished input shaft

TNT-2 YWIN

Developed for applications the place the irrigation system could want to be towed

This gearbox is the best answer for a towable irrigation technique. Growers usually desire this gearbox more than a gearbox with a towable hub. Basically disengage the worm and tow your technique to its doing work place, then re-engage the worm and you are ready to operate. The CX coupler is the best compliment for the TNT-two gearbox owing to the ability to control coupler disengagement at the gearbox.

The UMC® patented TNT-2 ultimate drive gearbox is developed especially for programs exactly where a center pivot or lateral go/ linear irrigation technique needs to be towed. The gearbox offers the capacity to disengage the worm gear and enables customers to transfer methods from a single spot to yet another without demanding a Towable Hub incorporate on.

Functions and Positive aspects

- two.25″ output shaft

- 50:one equipment ratio

- Dual enter seals with triple lip output seals

- Bronze equipment optional

- Enter shaft guard

- Exterior seal protectors for input and output seals

- Prime oil fill plug

- eleven-Bolt mounting sample

- Complete cycle growth chamber with stainless steel cover

- Filled with extreme strain worm gear oil

- Steel output shaft and enter shaft

- Tapered roller bearings

- Contains carriage bolts and nuts

- Dual ended input shaft

760-UV Bronze YWIN

Created for the most severe conditions exactly where an extended output shaft is necessary.

Growers normally use The UMC® 760-UV bronze gearbox for the most intense programs the place an extended output shaft is essential. The gearbox is designed for greater annual hours of operation whilst managing the weighty masses knowledgeable on corner techniques and lateral transfer carts as effectively as the most severe discipline circumstances in which wheel rutting is notable, soil is large, and tower weights are increased.

The UMC® 760-UV Bronze closing push gearbox is our premier and most resilient gearbox with an extended output shaft created for the most excessive growing conditions. It functions a high toughness aluminum bronze bull gear and a warmth dealt with metal worm gear offering it a significantly greater load capacity than the regular 760-UV. Additionally, this equipment mixture greatly minimizes equipment dress in, extending the helpful existence of the gearbox. It also features a 2.5″ output shaft to accommodate a lot more overhung load. It is made for use on centre pivots, corners, lateral move/ linear irrigation methods and carts in which a fifty two:one equipment ratio and extended output shaft are regular specifications.

Characteristics and Positive aspects

- two.5″ output shaft

- 52:1 gear ratio with a 25° pressure angle

- Unique dual input and output seal layout

- Bronze Equipment

- Warmth Treated Metal Worm Equipment

- Bigger input bearings

- Enter shaft guard

- External seal protectors for input and output seals

- 11-Bolt mounting sample

- Full cycle growth chamber with aluminum go over

- Loaded with severe strain worm gear oil

- Steel output shaft

- Tapered roller bearings

- Consists of carriage bolts and nuts

- Dual finished input shaft

- Also Obtainable Assembled in the United states of america

UMC is the business chief in gearbox technology. More than 37 year history they have launched numerous sector modifying gearboxes this kind of as the patented TNT gearbox, the 740, the 760, the 775 and far more. UMC continue to determine and redefine market specifications for gearbox performance, high quality, features and technology. UMC gearboxes are function built to do the task. Never ever over-engineered.UMC stands behind its items and is committed to production the very best goods for a global market.