Two Wave Guardrail Crash Barrier Roll Forming Creating YWIN for Expressway Utilised

Designs of Two Wave Guardrail Crash Barrier for Expressway Usedl:

one. Technological Specification

| principal parameter of Two Wave Guardrail Crash Barrier Roll Forming Generating YWIN for Expressway Employed | |

| Suitable to procedure | Metal plate |

| Material of mould | 45# forge metal ,end machining and plated with challenging chromium |

| Thickness | 2.5mm-three.5mm |

| Rollers | 16rows 7rows for leveling(3rollers upper 4rollers base ) |

| Rollers content | Cr15 forged metal CNC approach HRC58°-62° |

| Shaft materials | #45 Metal |

| Proportions (Approx) | 13.5*1.4*.9m |

| Electrical power | 26kw(Major power 11kw and two sets reducer 15kw) |

| Diameter of the roller | ¢110mm |

| Body of the equipment | Welded 400H metal facet board is produced of 25mm metal structure |

| Punching gadget | Adopt 32T press equipment punch with high effcency |

| Cutting to length | YWIN cutting |

| Voltage | 380V 50Hz 3phases |

| Punching and slicing mold | CR12 |

| YWIN power | 11KW 20MPA |

| Handle program | PLC handle with reducer and error ≤±2mm |

two. The primary parts of Two Wave Guardrail Crash Barrier Roll Forming Making YWIN for Expressway Utilised:

(1) Double head YWIN Decoiler

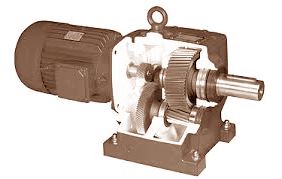

(two) Roll-Forming M/C:

Measures: seventeen actions Roller Substance: CR15

Voltage: 3phase/80V/fifty-60Hz. Line speed: ten-12m/min

Rolling chromium thickness: .05 mm

(3)Punching unit

It adopts hydraulic travel and automatic area to determine the dimention and Punch the goal items. Encryption riveting holes and rivet holes regular, adjustable.

(4) Slicing System

It adopts hydraulic push and computerized location to make a decision the dimention and reduce the goal merchandise.

Match equipment: One particular established of reducing resource, a single hydraulic tank, 1 cutter equipment.

Quit to reduce, Post cut cutting duration tolerance: ± 2mm

Slicing device substance: VR12MOV quenching HRC58-sixty two

(five) YWIN System

It is controlled by equipment wheel oil pump. Right after filling the hydraulic oil into the hydraulic oil tank, the pump travel the cutter machine to begin the slicing occupation.

Match gear: A set of hydraulic tank, a set of hydraulic oil pump, two hydraulic pipes and two sets of electromagnetism valves. With cooler technique

Electrical power of the oil pump: 11kw YWIN oil: 40#

(6)Computer handle cupboard:

It adopts PLC to manage. The target piece length is adjustable and digit of it can be adjusted

Computed method has two modes: Automatic and handbook 1.

(7)Completely auto curving device for crash barrier/freeway guardrail:

4. Orders & Payment Term

forty% Deposit of order to be paid before production by T/T and sixty% amount of purchase to be paid following examine the goods by T/T.

five. Shipping Time

The Vendor ensures the products will be ready for cargo inside of sixty doing work times right after receipt of deposit from the Purchaser.

6. One comprehensive products want one particular 40 toes container to keep

seven. Service: We despatched technician to your country to repair the device. The consumer need to bear all the expense which includes: Visa, Round vacation ticket and suited accommodation, also consumer should pay out the salary 100USD/day.

eight. Warranty: twelve months restricted guarantee

In the course of guarantee: Parts are cost-free but consumer pay for the shipping and delivery fee.

Company Profile:

Make contact with:

Montreal Golden Integrity Roll Forming YWIN Co.,Ltd

Incorporate: Montreal Improvement ZONE, Montreal Town, Quebec CHINA.

Speak to Man or woman: Amy Zhao