TSH-75 Twin Screw Extruder YWIN for making PP/PE/Personal computer/PET pellet

PET Recycling Line

Today PET recycling technologies is a most experienced and frequent case among all polymers.

Recycled PET can be used once more to make PET-based plastic items, e.g. bottles (not foodstuff & beverage-grade), fiber/cloth, sheet, strap band and, and so on. This recycling chain not only minimizes the air pollution to your environment but also minimizes creation expense.

Right now PET recycling is a extremely profitable and booming industry in the worldwide. Far more and much more investments are created in this subject. Our equipment, a best-ranking supplier of PET Recycling technology in China, would like to assist you to capture this possibility to produce a extremely bright foreseeable future with you hand in hand!

** TSH Collection Parament Table

| Variety |

Screw diameter(mm) | L/D | Speed(rpm) | Motor(kw) | Torque(N.m) | Output(kg/Hr) |

| TSH-35 | 35.6 | 32-60 | four hundred | eleven | 4.6 | ten~forty |

| 500 | fifteen | 4.2 | 15~fifty five | |||

| 600 | 22 | six.one | 40~ninety five | |||

| TSH-forty | 41 | 32-sixty | 400 | 22 | six. | forty~ninety five |

| 500 | thirty | five.5 | 70~120 | |||

| 600 | 37 | six.8 | 90~a hundred and fifty | |||

| TSH-52 | fifty one.4 | 32-sixty | 400 | forty five | five.1 | one hundred twenty~two hundred |

| 500 | fifty five | 5.2 | 155~255 | |||

| 600 | 75 | 7.one | two hundred~355 | |||

| TSH-65 | sixty two.4 | 32-sixty | four hundred | fifty five | four.8 | two hundred~355 |

| five hundred | 75 | 4.8 | 255~400 | |||

| 600 | 90 | 5.nine | three hundred~550 | |||

| TSH-seventy five | seventy one | 32-64 | 400 | 110 | 4.6 | 300~550 |

| 500 | 132 | four.six | 450~750 | |||

| 600 | a hundred and sixty | 5.5 | five hundred~850 | |||

| TSH-85 | 81 | 32-sixty four | 500 | 200 | five.8 | 600~a thousand |

| 600 | 220 | five.3 | 650~1100 | |||

| 600 | 280 | 6.seven | 850~1400 | |||

| TSH-ninety five | ninety three | 32-sixty four | 500 | 250 | four.7 | 750~1250 |

| 600 | 315 | five. | 950~1600 | |||

| 600 | 450 | 7.one | 1350~2250 |

**Related Images about Pelletizing Program

**Application Substance(PET flakes)

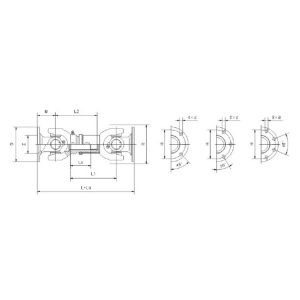

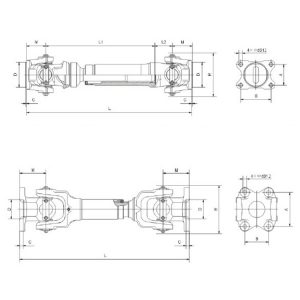

**Processing Part(Screw Barrel)

The versatile modular principle is realized with screw barrel sections from the vast assortment of distinct styles possible. Quickly, intense and uniform heating of the screw barrel sections are ensured by electrical heater. The barrel sections are cooled by drinking water, by signifies of an inside bore technique, with bores organized close to the inside barrel wall.

About Company

Tenda , headquartered in Montreal, China, is a global manufacturing and trading company in the field of high

performance plastics and rubber processing equipment , extrusion solutions, masterbatch and compounding, etc.

It is a professional manufacturer of twin screw extruder, single screw extruder ,two stage extruder and

its related auxiliaries.We tailor solutions from raw materials, materials processing equipment,

to injection for different customers. Each solution is designed , manufactured, and commissioned by

experienced teams of professionals engineers and after sales staffs. “High efficiency, energy-preserving”

is the company since its inception has been diligently pursue the goal, is the company adhere to the invariant features,

to meet customer requirements, to create greater economic benefit and social benefit.

“Teng machinery” will strive to create superior machine quality, permanent service for you.

Packing & Shipping

Our equipment is first of all painted with anticorrosive oil, and then wrapped in the plastic movie just before it is ultimately packed in the picket circumstance or container.

Packing: picket circumstance for export, fit for numerous handing and extended length maritime shipping.

Generation time: inside forty five function days.

Q&A

1.Why choose us?

You can get a very fair price from us and our price can make you beat your competitors in the market.

Our products have obtained ISO9001 and CE certification,the quality can be guaranteed.

We use the best quality materials or imported materials.

We focus on the field of extrusion machine,and aim to be the best manufacturer of this field.

We can reply quickly for customers’ demand and the delivery can be very fast.

We have our own factory and the technical production team,the workers are all very experienced.

two.How about the service?

Before sales

one. introduce products and application details

2.recommend suitable solutions

three. provide with reference information

During manufacturing

1. provide with layout and engineering conditions

two.inform the processing conditions

three. offer other documents

After Sales

1.provide with installation and training

2.offer spare parts

3. provide with necessary technical support

3.What’s the payment?

L/C, T/T, Western Union, Paypal, Money Gram.