3 Waves Guardrail Creating YWIN

Guardrail drawing dimensions:

The primary structure for Three Waves Guardrail Generating YWIN:

Street guardrail equipment consists of 10T hydraulic feeding gadget, transmission device, leveling system, two sets of front punching unit (one with shearing), energy shipping and delivery platform, forming roller path and host (such as manual platform), pc manage Box, finished item feeding gadget and other parts.

Three Waves Guardrail Producing YWIN creation procedure:

Manual decoil ~manual feeding~leveling~punching hole ~guide feeding ~roll forming ~cutting the set duration~output

Three Waves Guardrail Generating YWIN parameter:

| Material employed and its thickness | 2.seven to four.1mm |

| Doing work speed | ten-13m/min |

| Numbers of the roll stations | thirteen teams major roll stations include 7 rolls for levelling |

| Power of levelling motor | seven.5Kw |

| Material of rollers | Gcr15 Bearing metal quenching HRC58°-62° |

| Material of principal rolls | 45# Large-top quality steel quenched and tempered |

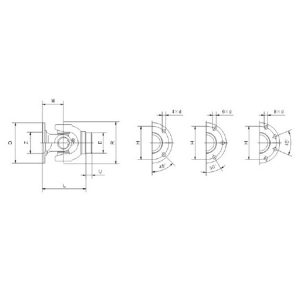

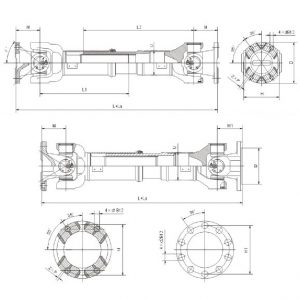

| Shaft diameter of primary rolls | Φ95mm |

| Electrical power of main motor | 37Kw |

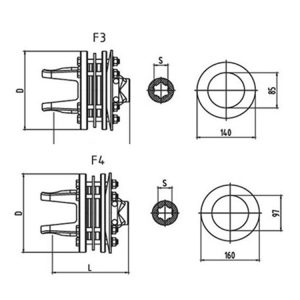

| Transfer Kind | YWIN common joint transmission |

| Forming machine construction | Pillar variety |

| Diameter of pillar | fifty mm±0.002mm The material is 40CR, quenched and tempered, elevated hardness, wireless grinder processing, floor plating, and when once more on the wi-fi grinder two processing |

| The guidebook column slider is produced of forged steel. The guide column gap and the bearing hole are all machined when to make sure precision. | |

| YWIN machine punching motor energy | 11kw,Pressure:20Mpa |

| Punching and reducing mould | Cr12 |

| Shear blade warmth therapy | HRC58°-62° |

| Punching and cutting methods: YWINally driven, stepped uniform punching, sloping flat shear. (Cylinder up and down movement to full the eighteen punching, and slicing, the actual knowledge of 150T strain can comprehensive the movement, light-weight energy saving, effortless routine maintenance) | |

| The cylinder diameter is 300MM and the stress reaches 250T | |

| With a energy feeding platform, the motor energy is 4KW, the length is six.5m, the two sides are evenly outfitted with a track-to-wheel, and a 1m spacing system is a pinch roller. | |

| Profile independent middle gap positioned in front of shear cylinder stress 50T | |

| Digital handle program | The complete machine adopts industrial computer PLC frequency conversion handle (Japan Mitsubishi) |

| Reduce off the size mistake | ≤±2mm |

| YWIN Proportions(mm) | 10400×2800×1700 |

Three Waves Guardrail Making YWIN reference photograph: