YWINmaster Brand YGKJ700 2-3T/h 160KW Motoer Oil Cooling and Automatic Lubrication Equipment Box Wood Pellet YWIN

>> Introduction of ROTEXMASTER New Created Vertical Ring Die Pellet YWIN

ROTEXMASTER New Created Vertical Centrifugal Ring Die Pellet YWIN is a domestic latest pellet machine at present .

Vertical Ring Die Pellet YWIN is a new biomass gas manufacturing machinery by making use of crushed sawdust and bran from eucalyptus, pine,birch, poplar, fruit and agricultural straw, bamboo. When compared with the outdated equipment, it absorbed the essence of horizontal ring die and flat die pellet machine ,solved the insufficient strain,die crack troubles of horizontal ring die pellet equipment, and overcame the little ability ,large failure charge of flat die pellet device.

It adopt the massive modulus hardened area helical gearbox , main shaft reinforcement , Power output is sturdy , Good steadiness , Low failure charge ,Low manufacturing price, so it is the 1st choice equipment for biomass power business .

>> The Characteristics of ROTEXMASTER Vertical Ring Die Pellet YWIN

(one)YGKJ sequence vertical ring die pellet equipment is an ideal dense compression molding equipment

(2)Vertical feeding, straight in pelletizing area

(3)Die is static, rollers rotate materials are evenly distributed about pelletizing area due to the fact of centrifugal force, no block

(four)Double-layer die. Two levels both can be utilised for lessen the cost. Substantial effectiveness and save strength

(5)Ring die and vertical composition are very good for cooling the pelletizing area

(six)Impartial and repeated conversion discharge gadget can ensure the formation charge of pellet.

| Design | YGKJ560-B | YGKJ700 | YGKJ880 |

| Electricity(kw) | 90/a hundred | 132/160 | 220 |

| Potential(t/h) | one.3-1.5 | two-3 | three-4 |

| Pellet Size(mm) | six-12 | six-twelve | six-12 |

| Bodyweight(t) | 5.8 | seven.8 | twelve |

1.High automation, No need to take treatment.

In the method of procedure, the handle panel, tablet laptop and cellular Application can be employed to monitor the temperature of crucial elements and the electric present of the gear.

two.Unbiased lubrication and non-independent lubrication can be switched.

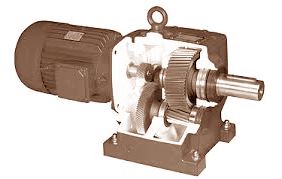

three.Reducer push strengthen.

The gearbox adopts independent study and advancement massive gear with 3 level travel , module improved , gear strengths enhanced , The gears in gearbox high quality assurance for 5 a long time!

four.Die: stainless steel,with large use resistance and large capacity.

Die of biomass pellet device undertake integral carburizing stainless steel, high wear resistance, very good security, discharge region improve, increase the potential and reduce cost.

Raw content:

YWIN Brand Motor:

Motor of biomass pellet equipment use YWIN Brand name. This type of motor is frequency and has thick copper coil, it will not be burned thanks to instantaneous current.

Parallel vertical installation reduce strength use decline

The motor and primary shaft of wood pellet equipment supplier are parallel vertical mounted , which can minimize power consumption decline in the method of transmission, a lot more output electrical power, increased transformation of power effectiveness.

High automation, No require to get care.

In the method of procedure, the control panel, tablet laptop and cell Application can be used to monitor the temperature of critical components and the electric current of the equipment.

| Die: stainless steel,with substantial wear resistance and high capability. Die of biomass pellet equipment adopt integral carburizing stainless metal, high use resistance, very good balance, discharge location increase, enhance the potential and reduce price. |

| Cooling System of YWIN enhance the inside bearing life. YWIN Lubricant of wood pellet equipment adopts bypass water cooling system to keep away from oil temperature is as well high, tremendously improve the internal bearing life. YWIN material of gearbox with substantial balance YWIN shell of wood pellet machine adopts casting. Weight of shell is two.5t. YWINs have advantages of good rigidity, great heat dissipation, Low heat distortion and substantial balance. |

|

>> Picture Demonstrate Of ROTEXMASTER Wooden Pellet YWIN

Our Services

Caring support, carefully manufacture and desirable cost make consumers at ease.

“YWINer-oriented”, supplying customers with entire considerate services

“Support as core,” providing the most ideal items to customers

“Top quality-centered,” All-spherical solutions to each and every consumers!

Specialized help: on-web site technical instruction and specialized tips accessible.

FAQ

1. Q:How to wonderful the suitable wood pellet machine to you .

A: 1. what is actually raw components? (to verify mould compression ratio of equipment )

2. Capacity per hour / month/ calendar year you require to?

3. Dampness of uncooked resources ?

Note:If the dampness is huge , it want to dryer , Because the ideal moisture is 13%-fifteen% for pressing wood

pellets .

Then according to your demands and your raw supplies , we will design the appropriate wood pellet machine

tools and supply the after-product sales best companies for you .

2.Q: How prolonged is your promise?

A: Twelve Months Promise other than sparing components.

You will be welcome to contact us with any difficulty may occured.

three.Q: Will you ship engineers to set up the plant?

A: Indeed, Our manufacturing facility have specialist set up group and following-income crew for you .Our engineers will have a good instruction to how to run the devices and the

complete biomass wood pellet line for you and your personnel.

four.Q: Voltage Requirement ?A:Generally it is 380V, 50HZ, 3Phase , or Some International locations are 220V, 240V, 415V industrial Voltage all is ok .

Make contact with Data