Description

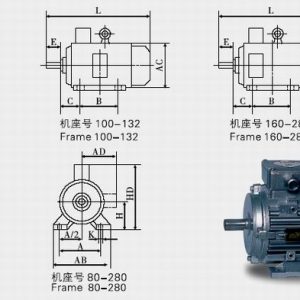

Y series motors are low-voltage three-phase asynchronous motors, which are basic series for general purpose. This series motors can meet requirements for general for purpose motors interiorly and overseas with frame range from 80 to 315.This series motors designed according to the national unified standard.

Y series motors have the advantages of high efficiency , energy saving , excellent operation performance , small vibration , lower noise , long service life , high reliability and easy maintenance. Mounting dimensions and the power grade completely conform to IEC standard . They are in class B insulation ,IP 44 degree for protection and cooling mode of IC411 . The rated voltage and frequency insulation of Y series are respectively 380v and 50HZ . Y connection is adopted for motors below 3kw(3kw included ) and △ connection is adopted for those above 4kw (4kw included ) . Y series motors are commonly applied in machinery equipment without any special requirement.

Feedback

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Package

Wooden Case/Container and pallet, or as per customized specifications

Lead Time

15-25days samples. 30-45days offcial order

Certificate

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

- Mail/Skype:

- WhatsApp/Wechat:

Surface Treatment

Annealing, natural anodization, heat treatment, polishing, nickel plating, chrome plating, znic plating,yellow passivation, gold passivation, satin, Black surface painted etc.

Products Available

sprockt chains, pulley, shafts(axles, spline shafts, dart shafts),gears (pinions, wheels gear rack) bearing, bearing seat, bushing, coupling, lock assembly etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC :

Technicians self-check in production,final-check before package by professional Quality inspector

Advantage

Quality first Service superior , Advanced equipment,Experienced workers,Perfect testing equipment