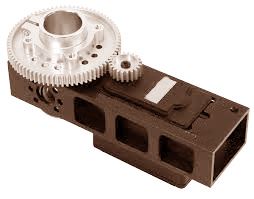

Description

Ideal for use in main spindle drives on machine tools. Rapid change between high speed for finishing cuts and high torque for heavy-duty machining. Shaft output: solid or flange shaft

Two-speed gearbox with loss-optimized direct gear and integrated actuator controller with SensorShift. Two sizes. Two backlash classes. Two ratios in the transmitted gear. Flange shaft or solid shaft. Various bearing options. Splash lubrication or circulation lubrication (optional) for extremly high speeds. Easy and secure motor mounting.

Shaft design

Flange shaft

Solid shaft without key

Solid shaft with two keys

Housing Designs

Short bearing distance

Middle bearing distance

Long bearing distance

All designs can be delivered with a cooling flange as an option.

Bearing Design

Deep-groove ball bearing

Angular ball bearing

Cylindrical roller bearing

Mounting Positions

Any mounting position.

You can find the explanation of the mounting positions and the respective quantities of lubricant in the document Quantity of lubricant for gear units ID 441871

Lubrication

Splash lubrication

The splash lubrication is suitable for standard applications in a 2 speed planetary gearbox

closed gear unit housing.

Circulation lubrication with external tank

For high heat generation an external tank with min. 10 times volume of the gear unit filling can help. If required the tank filling can be brought to the optimum operating temperature by an additional heat exchanger.

Position of inlet and outlet of the lubricant according to the mounting position.

Position of oil inspection glass or oil level indicator (option) according to the mounting position.

Gear switcher with SensorShift

The position of the actuator is recorded with SensorShift (an electronic sensor).

An actuator controller integrated in the switcher evaluates the position signals and precisely controls the switching motor.

Advantages:

Connection in compatibility mode: Plug&Play for standard switcher

Provision of relay and cables in the control cabinet by the customer not necessary (for binary connection)

Integrated smooth start preserves the mechanical system

Significantly reduced programming effort for the switching process

The switching process is not time-critical for the machine controller and can be executed in the background

Automatic repetition of the switching process in the case of a switching fault

Wear-free, contactless recording of position

Switching to neutral gear (option) possible from any gear

Two-speed Switching

1st gear based on a high-precision helical geared planetary gear unit

Loss-optimized direct gear

Neutral gear position (optional)