Merchandise Description

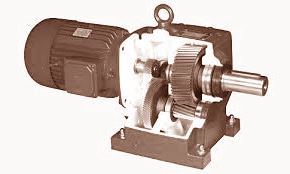

OEM Professionally Worm Tail YWIN Pinion Gear YWIN With Motor

Producing procedure :lathe machining

Screening gear:projector

We are willing to offer you with sample for screening, we have sixteen-yr producing and solutions activities.

We are ISO 9001: 2008 licensed agency.

Our Solutions

| YWIN YWIN | Equipment/ Automotive/ Agricultural YWIN/ YWIN/ Marine Mining/ YWINs/ Valves Oil and Gas/ Electrical/ YWIN |

| Supposed Software | Shafts Valve Components Automated Doorway Factors Cable/ Digital Connector Fireplace Suppression Program Elements Fittings/ Fasteners Gears/ YWIN Roller Bearings |

| Lead Instances Accessible | Max: two Weeks (On First Buy) Hurry Companies Accessible |

| YWIN YWINs | ISO 9001:2008 PPAP RoHS Compliant |

| Extra Abilities | CAD Design and style Services CAM Programming Solutions Coordinate Measuring YWINs (CMM) Reverse Engineering |

| Gear Record | From straightforward two-axis turning to seven-axis, switch-mill-drill CNC Swiss-kind equipment, molding equipment/ stamping equipment computerized lathe equipment/ spring equipment. |

| Materials (YWINs or plastic) |

Alloy Steels/ Aluminum/ Brass/ Bronze Alloys Carbon Metal/ Copper/ Stainless Steel/ Instrument Metal Chilly Rolled Steel/ Bearing Steel Abs/ Delrin/ Nylon/ PVC |

| Tests equipment | Projector. Calliper, micrometer, plug gauge, ring gauge, thread gauge |

| Procedures (Particular Abilities) |

Broaching/ Hobbing/ Slotting/tapping |

| Tolerance | ±0.0002 in ±0.0051 mm |

| packing | For light objects: bubble pack individually to stop from damaging and scratches in transporting, then in carton for heavy objects: wrapped in PE bags and then in picket boxes |

Transport

1. We are prepared to supply with sample for high quality and perform testing.

2. Supply time:in twenty working times .

FAQ

Q1:How to ensure the High quality of YWIN Areas?

A1:we are ISO 9001-2008 accredited agency. we have the integrated system for industrial components top quality manage. We have IQC (incoming quality control), IPQCS (in approach top quality manage segment), FQC (closing quality control) and OQC (out-going quality control) to management each and every process of industrial areas prodution.

Q2:What’s the Advantage of Your Parts for YWIN Goods?

A2:Our advantage is the aggressive charges, rapidly supply and large high quality. Our employees are liable-oriented, friendly-oriented,and dilient-oriented. our YWIN parts products are highlighted by rigid tolerance, smooth complete and prolonged-life overall performance.

Q3:what are our machining equipmengts?

A3:Our machining equipments include CNC milling equipment, CNC turning devices, stamping

equipment,hobbing devices, automatic lathe devices, tapping devices, grinding equipment,

screw devices, slicing devices and so on.

This autumn: What shipping techniques our use?

A4:Typically talking, we will use UPS or DHL to ship the items. Our customers can get to the

products inside three times.

If our customers do not require them urgently, we will also use Fedex and TNT.

If the goods are of heavy bodyweight and huge volumn, we will ship them by sea. This way can conserve

our customers a lot of income.

Q5:Who are our main clients?

A5:HP, Samsung, Jabil Group,Lexmark,Flextronic Team.

Q6:What supplies can you deal with?

A6:Brass,bronze,copper,stainless steel, steel,aluminum,titanium And plastic.

Q7:How Extended is the Supply for Your YWIN Component?

A7:Usually talking, it will consider us 15 operating days for machining components and twenty five working days for

the for stamping elements merchandise. But we will shorten our guide time in accordance to customers’ requires if we are in a position to.