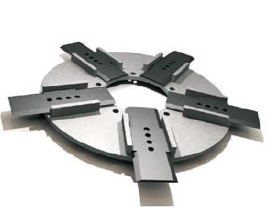

OEM YWIN YWIN Equipment Box for Motocycle Auto Spare Elements

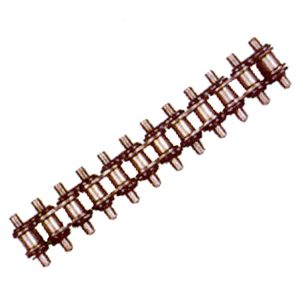

gear box,casting gearbox,iron casting gear box,steel casting equipment box,

YWIN parts,sand casting parts,precision casting parts,stainless steel casting parts,steelcasting parts,steel casting ,stainless steel casting,carbon steel casting,casting,metal casting

Requirements

Ductile iron Sand YWIN H2o pump bodys

1.rigorous QC & well timed supply

two.YWIN:BS,DIN,ASTM

3.good at custom made

4.OEM

YWINized OEM YWIN YWIN Gear Box for Gear Box Spare Parts

manufacturing particulars:

one.Material: GGG40.

2.Measurement:CN150X150mm.

3.Weight:three.4kg.

four.Technological method: Sand casting+CNC Machining.

five.Inspection: mechanical homes, leaking totally free examination carried out by in-home or third get together

six.Use: Submersible pump body .

YWINized OEM YWIN YWIN Equipment Box for Gear Box Spare Areas

OUR MACHINING PROCESS :

Occupies an area more than 6,000 square meters

More than 40pcs big CNC lathes Ø500 – Ø1200

Machining center 1400 x 825 x 1000mm 4 axis

Can provide services: turning milling grinding drilling inserting broaching boring polishing

Surface preparation: passivation polishing plating coating painting zinc phosphate dacrotized / dacromet technology

OEM YWINized YWIN Iron YWIN Parts with Drawings or Samples

one.ISO9001-2008.

two.Has YWINd euipment and over 15 years experience.

three.price: competetive price , YWIN made.Experience & Reasonable QC that you can reply on.

4. Process: YWIN made.Experience & Reasonable QC that you can reply on Each part would be given 100% test and tryout before shipment.

5. Adequate supply capacity. Punctual delivery time.Forging: We can provide forged ring, open-die forging, forged shaft, forged bush, forged shape, drop forging, precision forging, hot-pressed part, upset forging, hot-upset part, forging casting, forged disc, perforated disc.

OEM YWINized YWIN Iron YWIN Parts with Drawings or Samples

one.ISO9001-2008.

two.Has YWINd euipment and over 15 years experience.

3.cost: competetive price , YWIN made.Experience & Reasonable QC that you can reply on.

four. Process: YWIN made.Experience & Reasonable QC that you can reply on Each part would be given 100% test and tryout before shipment.

five. Adequate supply capacity. Punctual delivery time.Forging: We can provide forged ring, open-die forging, forged shaft, forged bush, forged shape, drop forging, precision forging, hot-pressed part, upset forging, hot-upset part, forging casting, forged disc, perforated disc.

OEM YWINized YWIN Iron YWIN Parts with Drawings or Samples

Material specification: 1. carbon & low alloy steel

2. stainless steel

3. high alloy & wear resist steel

4. gray iron ductile iron

5. malleable iron

6. alloyed cast iron

7. aluminum alloy

8. cooper alloy

9. zinc alloy

Range of casting weight: 0.50kg-450kg

Heat Treatment: Normalizing

Quenching

Tempering

OEM YWINized YWIN Iron YWIN Parts with Drawings or Samples

OUR MACHINING PROCESS :

Occupies an area more than 6,000 square meters

More than 40pcs big CNC lathes Ø500 – Ø1200

Machining center 1400 x 825 x 1000mm 4 axis

Can provide services: turning milling grinding drilling inserting broaching boring polishing

Surface preparation: passivation polishing plating coating painting zinc phosphate dacrotized / dacromet technology

OEM YWINized YWIN Iron YWIN Parts with Drawings or Samples

OUR MACHINING PROCESS :

Occupies an area more than 6,000 square meters

More than 40pcs big CNC lathes Ø500 – Ø1200

Machining center 1400 x 825 x 1000mm 4 axis

Can provide services: turning milling grinding drilling inserting broaching boring polishing

Surface preparation: passivation polishing plating coating painting zinc phosphate dacrotized / dacromet technology

| Substance | one.Sand casting&Gravity casting&Minimal strain die casting: A356/A319/A413/ZL101/ZL102/ZL104/ZL107/LM6//LM/20/LM25/EN AC-42100/EN AC-42200/EN AC-43000/ EN AC-43200/EN AC-43300/EN AC-43400/EN AC-44200/EN AC-44300/EN AC-46000/EN AC-46200 2.Higher strain die casting: A380/A390/A360/ADC10/ADC12/ENAC-43400/ENAC-44300/ENAC-44400/ ENAC-46000/ENAC-46100/ENAC-46200/ ENAC-46500/ENAC-47100 3.CNC machining casting: 6061-T6/6063-T6 |

| Provider | Sand casting, Gravity casting, high pressure die casting,low pressure die casting and CNC Machining casting. |

| Equipment of YWIN | one. High stress die casting machining:125T/180T/250T/280T/500T/800T/1250T two. Gravity casting device: five creation traces 3. Low strain die casting machining: 1 production line four. Sand casting equipment: six generation lines five. Degassing equipment and options to refine the materials six. Machining: 5Sets CNC YWINs3 sets Milling devices 3 setsTurning machines 10 sets drill and faucet machines |

| Tests facility | spectrometer, tensile test equipment, hardness test machine,CMM dimension report |

| Certification | ISO9001:2008/Rosh/SGS/BV |

| YWIN | ASTM, DIN,JIS, EN, ISO, GB specifications |

| Computer software | Professional/E,UG, Solidworks, Vehicle CAD, PDF |

| YWIN machining | CNC turning, milling, drilling, grinding, cutting, reaming and threading |

| Completed | Sprucing, sand blasting, warmth treatment method, portray, powder coating, anodizing,electroplating, Chrome plating, mirror sprucing. |

| Merchandise | All varieties of aluminum casting: include automotive parts, railroad parts,medical parts, maritime areas, lights components, pump body, valve elements,architectural areas and furnishings parts so on |

| two.Substantial pressure die casting: A380/A390/A360/ADC10/ADC12/ENAC-43400/ENAC-44300/ENAC-44400/ENAC-46000/ENAC-46100/ENAC-46200/ 3. CNC machining casting: 6061-T6/6063-T6 |

|

| Processing | Sand casting, Gravity casting, high stress die casting, reduced strain die casting and CNC Machining casting. |

| Style | As for every the customer’s drawings |

| Equipment of YWIN | one.Large stress die casting machining: 125T/180T/250T/ 280T/500T/800T/1250T two.Gravity casting machine: five generation traces 3.Lower pressure die casting machining: one production line four.Sand casting device: 6 generation traces five.Degassing products and chances to refine the materials 6.Machining: 3Sets CNC YWIN3 sets Milling device 3 sets Turning machining ten sets drill and faucet device |

| Screening Facility | Spectrometer, tensile check equipment, hardness take a look at equipment, CMM dimension report |

| Certificate | ISO9001:2008/SGS |

| YWIN | ASTM, DIN,JIS, EN, ISO, GB standards |

| Computer software | Pro/E,UG, Solidworks, Automobile CAD, PDF |

| YWIN Machining | CNC turning, milling, drilling, grinding, reducing, reaming and threading |

| Completed | Sprucing, sand blasting, heat treatment, portray, powder coating, anodizing, electroplating, Chrome plating, mirror polishing. |

| Provider | OEM service obtainable,make according to customer’s drawings |

| Products & Application Scope | All sorts of aluminum casting: consist of automotive parts, railroad elements, healthcare parts, maritime parts, lights components, pump body, valve elements, architectural areas and furnishings areas so on |

| Benefits | 1. Lutz operates with in excess of 8 several years in Aluminum casting for Japanese and German market 2. Lutz have 4 casting kinds making strains three. In close proximity to Sea Port and Air Port 4. Handed ISO9001:2008/SGS 5. OEM provider in accordance to customers’drawings 6. From YWIN to finished floor, owned casting, sharpening and plating workshops.Wcan supply very good good quality and rigorous shipping time 7. With samples and order: We can provide dimension report,Chemical composition and Mechanical qualities 8. Manage material with spectral and thermal examination products (density and processing) nine. Spectral evaluation of raw-material and liquid melt, batch prior to casting. |

YWINized OEM YWIN YWIN Gear Box for Gear Box Spare Components

Q: Why choose YWIN product?

A: We shengao have our own plant– Montreal YWIN machinery Co., Ltd, therefore, we can surely promise the quality of every product and provide you comparable price.

Q: Do you provide OEM Service?

A: Yes, we provide OEM Service.

Q: Do you provide customized gearbox?

A: Yes. YWINers give us drawings and specifications, and we will manufact accordingly.

Q: What is your payment term?

A: We provide kinds of payment terms such as L/C, T/T, Paypal, Escrow, etc.

If there’s anything I can help, please feel free to contact with me.

If you are fascinated in any of our items, you should click your mouse and deliver email to us by underneath technique. We will reply to you winthin 12 hrs.