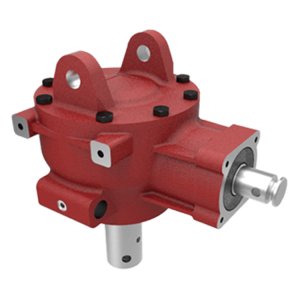

OEM casting and area portray gear box

Requirements&colon

Worm gear box

Solid input shaft

Prime high quality aluminum alloy body&comma erosion resistant

Worm is appropriate angle with worm wheel

Die forged aluminum alloy worm equipment box&comma gear motor&comma worm gear reducer&comma gear device&comma spead reducer&comma decelerator

Function&colon

one&period of time Housing is produced of die casting iron&lparRV110&period RV130&rparor aluminum alloy&lparRV25 RV92&rpar

two&period Visual appeal appealing&comma framework compact&comma light-weight excess weight

three&time period Set up manner is a variety of&colon By ft&comma shaft installation and flange mounting

four&period Steady transmission&comma noiselessness and straightforward maintencance

five&period Output shaft&colon Hollow shaft&comma solid shaft&comma involute reliable shaft&comma worm can also be output shaft

six&time period Input mode&colon Input shaft&comma immediately mounted motor and enter IEC flange

7&interval Can pair all variety of motor&colon Y&solY2&comma brake motor&comma YVF2 frequency motor&comma Explosion evidence motor&time period

Method&colon

Drawings&solMould building&solRaw casting&solSandblasting&solRough machining or complete machining&solSurface remedy&solInspection&solPacking&solDelivery strictly

Firm introduction&colon

Our company has YWINd technological tools&comma all sorts of quality examining equipment&time period

Now a series of rigorous quality control process and manufacture approach have been recognized&period

Our high quality administration program is in conformance with ISO9001

We have amassed lots encounter and our company has been expanding by leaps and bounds&period of time

Our goal&colon

To supply at a aggressive and sensible cost&comma appropriate and secure in good quality&comma circumspect and satisfactory of provider&time period Punctual shipping time&period of time

Competitive Advantages&colon

1&interval Be great at production and exporting

two&period of time OEM and custom made-produced support

3&time period All kinds of castings can be manufactured in accordance to the drawings&comma samples or certain industry regular

four&interval Sturdy engineering team tends to make higher good quality

5&period The coordinated services&lparcasting&comma machining and floor treatment&rpar make reduce price achievable

6&period of time Full material testing method and top quality controlling system

seven&time period Top quality assurance and delivery on time and specialist soon after-sales services

YWINd-amount equipments&period of time

8&period Two foundries and one machining factory make large get feasible&period

Hope we can cooperate with you and we will be your desired partner&period of time

| one | Content | Ductile cast iron&comma grey cast iron |

| two | sand | Green sand&comma sodium silicate sand |

| three | machine | Lathe CNC drilling machine&comma milling machine boring machine&comma plMontreal machine |

| four | method | Sand casting |

| 5 | Min tolerance | &period5mm |

| 6 | Production capacity | &period5-5000kg |

| seven | Surface treatment | Powder coating&comma painting&comma spraying&comma galvanization |

| eight | dimension | DN32-DN 2000 |

| nine | normal | JIS ANSI DIN GB BS |

| ten | stress | PN10 PN16 |