Mild steel roll forming framing equipment for modern design

our light-weight gauge steel home framing is an innoviate machine with vertex BD system.

emphasize of our device

1)considerably less electrical power use(7.5kw servo motor power,3.75kw hydraulic pump)higher efficiency,:complete line velocity 50meters/moment(punching speed:15meters/moment),great breakthrough of standard device concept,device will not be stuck while forming,significantly less rollers,but can make ideal item.

Easy to transport.

2)a single encoder is utilised by the whole line,to handle principal device and printer.only one particular signal is recognized to make sure punching and duration accuracy.

three)we use synchronous travel to make confident that reducing,web rib,notch cutting are a lot more precision.

4)1 encoder is utilised by the entire line,to control main machine and printer.only one sign is recognized to make certain punching and size accuracy.

5)The generation process checking is intuitive, and consumers can comprehend the rhythm of production in element by means of the application interface, such as: the comprehensive data of the components that have been accomplished and to be developed, the action measures of the processing station, the certain information of the creation feed, the distinct output of each and every shift, and so on.

6)The consumer can freely alter the manufacturing knowledge according to the certain info of the mold in the manufacturing tools to meet up with the demands of personalized manufacturing.

our mild gauge steel property framing equipment is an innoviate device with vertex BD system.

emphasize of our device

one)significantly less power intake(seven.5kw servo motor power,three.75kw hydraulic pump)large productiveness,:whole line speed 50meters/minute(punching speed:15meters/minute),wonderful breakthrough of classic equipment idea,device will not be stuck even though forming,significantly less rollers,but can make best solution.

Straightforward to transport.

two)1 encoder is employed by the entire line,to management main machine and printer.only 1 signal is acknowledged to make certain punching and length precision.

three)we use synchronous travel to make certain that cutting,net rib,notch reducing are much more precision.

four)one particular encoder is utilized by the total line,to handle principal machine and printer.only a single sign is recognized to make positive punching and size accuracy.

5)The creation process monitoring is intuitive, and customers can realize the rhythm of production in depth by means of the software interface, which includes: the in depth info of the factors that have been completed and to be developed, the action actions of the processing station, the certain info of the manufacturing feed, the distinct output of each shift, and so on.

six)The person can freely adjust the production data according to the distinct info of the mould in the generation tools to satisfy the requirements of individualized generation.

| Gentle Gauge Steel Property Frames Roll Forming YWIN |

Design:JCX-02 | Dimension:89*forty one*10 | Driving Approach Servo Motor |

||||||||

| ,Specification | |||||||||||

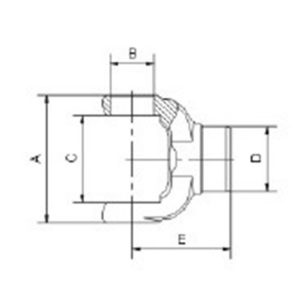

| one | Principal roll forming machine | Feeding unit | With four guiding rollers | ||||||||

| Roll forming unit | 12 roller stations, a single is to type and change the angle ( from 87 to ninety five) degree of base and web | ||||||||||

| Straightening system | With a single pair of horizontal shafts and two dangling rollers | ||||||||||

| Profile top unit | With one particular established of foremost rollers | ||||||||||

| Punching holes | |||||||||||

| Also have 3 holes at the finish of profile | |||||||||||

| Chopping device | three pieces of blades to preserve and lower the shape of profile | ||||||||||

| two | Control technique | Principal control method | One particular Lenovo laptop computer and a manage box inside of of based mostly frames of the machine | ||||||||

| Producing software | Special made to match with the planning application Vertext | ||||||||||

| Leaser Printing Device | Usa Matthews Leaser Printing Gadget for painting spray brand and set up indicating amount | ||||||||||

| Distant-manage device | Wireless remote-controller controls device to go forward or backward or quit | ||||||||||

| Manufacturers of main factors | PLC(self-produced),Relay (French Schneider), proximity switch(French Schneider), Encoder(Japanese Omron), Servo Motor(Montreale) All those elements requires with Internation Warranty Service. |

||||||||||

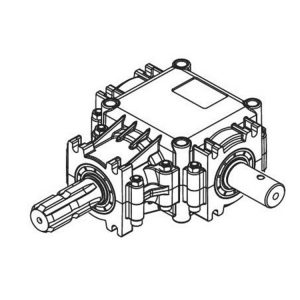

| three | Servo Program and YWIN Method | Servo motor | 5.5kw, taking with precision planetary equipment reducer | ||||||||

| YWIN Station | seven.5KW | ||||||||||

| YWIN oil injection 200 litre | |||||||||||

| Brands of primary parts | solenoid valve (Germanic YWIN) |

||||||||||

| 4 | Electrical decoiler | bearing capacity | 3 ton | ||||||||

| Expending or shrinking approach | Run the take care of to much more the 4 connection rods to absent from or close up to the cored shaft | ||||||||||

| brake | Cored shaft is double maintain tightly | ||||||||||

| Driving technique | Decoil uncooked content routinely | ||||||||||

| 5 | Manufacturing receiving System | length | 4m | ||||||||

| Getting technique | Obtain fashioned profiles and sideslip them pneumatically to saving table | ||||||||||

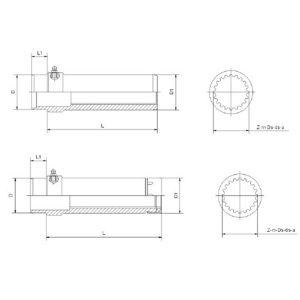

| 6 | Parameters of roll forming portion | roller | Content: GCr15 | ||||||||

| processing technic:CNC machining, heat therapy HRC58-sixty,then processed by CNC lathe, plating ultimately | |||||||||||

| shaft | Content: 40Cr | ||||||||||

| processing technic:CNC machining, quenching and tempering HRC28-32,then processed by CNC lathe, plating and polishing finally | |||||||||||

| fat | About 3.5 ton | ||||||||||

| ,parameters of fashioned profiles | |||||||||||

| 1 | Measurements |

|

|||||||||

| 2 | Forming velocity | The max speed 35m/min, typically 2-3 tons for each day | |||||||||

| three | substance | Q345,G550 galvanized steel strip | |||||||||

| ,connected parts and spare components | |||||||||||

| Spare areas | 2 sets of punching poles and down moulds | tools | A single set | ||||||||

| Handbook operation | One duplicate | Protective protect | completely-enclosed sort | ||||||||

| YWIN shade | As per device images or your desire | ||||||||||

Why gentle gauge metal residence?

YWIN using Light Gauge Steel (LGS) – also known as Cold Formed Steel – brings magnificant advantages over traditional building methods. In the frame are dramatically reduced building occasions, greater accuracy and build efficiency, minimised wastage, improved strength, durability and performance.