Top quality IS NOT Pricey IT IS PRICELESS.

People Keep in mind Quality Long Right after THE Cost IS Forgotten.

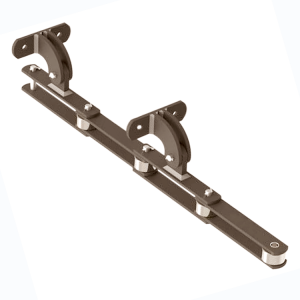

Merchandise Description

Scorching Sale Computerized Screw Auger Dry Mortar Packing YWIN is made to bag free flowing, non clumping powders and granules into valve baggage.

Packing Supplies

Notes: Not Limited(Ideal for powders and granulates inside of 5mm)

Comprehensive Images

Associate

How Hot Sale Computerized Screw Auger Dry Mortar Packing YWIN Works?

1, The bagger is fed from an overhead hopper,silo or mixer made up of the product to be bagged.

2, The packing cycle starts by managing a demand of substance from the overhead vessel into holding chamber of Hot Sale Automatic Screw Auger Dry Mortar Packing YWIN .

3, The filling cycle starts with the placement of baggage on to the nozzle. A depression of foot change or commence button on the controls commences the filling cycle. Primary feed auger, vibratory feeder, and valve auger feeder all come on collectively and run for flood fill of technique.

4, After flood fill setpoint has been achieved then sluggish pace filling kicks in. Principal feed auger slows down soon after acquiring signal from v.f.d, fills to pre-determined weight e.g ninety eight% then main feed auger shuts off.

five, Vibratory feeder and valve auger carry on to operate jointly till ultimate setpoint is reached.Quickly, precision filling is accomplished.

6, Filling cycle is total. In the situation of One Auger Filler replace bag and the cycle carries on.

Technological Information

| Substance | Lime,Gypsum,Sands, Cement , Dry Mortar,Tile adhesives, PVC Powder, Alumina, Zirconium, Carbon Black, Titaum White, Breadcrumbs,Granulated Rubber, Renders and comparable cost-free flowing merchandise. |

| Packing Scope | 5-fifty Kg |

| Potential | three-four t/h, relying on No. of spouts, item density, valve dimension, bag excess weight ,high quality of bag ,accuracy required and merchandise stream characteristics. |

| Filling Speed | two-3 luggage/min, depending on No. of spouts, merchandise density, valve measurement, bag bodyweight ,high quality of bag ,accuracy essential and item flow traits. |

| Accuracy | ±0.twenty five% |

| Electrical | 220-440V,three period,50-60Hz. |

| Dimensions Footprint | Footprint 900mm(w)*1440mm(d)peak 1950 mm (Under Silo) |

FAQ

Why don’t you answer the fololwing concerns for us to aid you uncover what you want ?

one, the content you want to pack and its dimensions(μm, mm), bulk density(kg/m3)

2, packing fat (kg/bag), capability (t/working day)

three, thorough description of production line