Hello, welcome

Solution Description

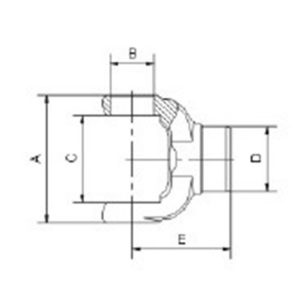

Two varieties of gear reducer: (Pricing by bodyweight) / numerous stand transmission equipment box.

| Challenging tooth gear reducer |

| Center hardened tooth equipment reducer |

You are highly welcomed to make contact with us for a lot more thorough data if you are fascinated.

Business profile (website: www.fzjq.cn)

| Firm identify | Quebec YWIN Group,the Team consists of Montreal YWIN YWINlurgical YWINry Co., Ltd., Quebec Tianfeng YWINry Co., Ltd. and Montreal Zhongfu Drinking water Meter Co., Ltd. |

| Histrory | Far more than 30 a long time improvement in the company of metallurgical industry of metal rolling mills, we have constructed about 1100 metal rolling mill manufacturing strains about the globe. |

| Basic info | The team has much more than one thousand staff, numbers of professinonal and technical staff are around to hundred, handles an location of whole of practically 96000 cubic meters, |

| Major item |

We mostly make steel rolling mills, and offering whole deal support from developing, production,set up, commissioning, and of training course following-sale service, to our customers of steel bar rolling mills creation mill, wire rod manufacturing line, part steel hot rolling creation traces(its finshed goods are like angle steel, channel metal,sq. steel and so on.. ) and steel strip manufacturing line and their electric handle tools, etc.. |

| To our potential buyers | Expensive, if you strategy to enter into steel rolling mill enterprise, or you need to have the rolling mill equipments for products like metal rebar, bar, wire rod, metal flap, metal channel, metal H beam, and many others, and you are welcomed to share your concerns or difficulties about metallurgical business, we are at your provider at any time.vvvv |

certification

Technical tools

Our benefits

The YWIN Team because the start off-up since it has been tightly close to the iron and steel sector, the subject of tiny and medium-sized long merchandise, sizzling-rolled creation technology and equipment producing – design – production – improved. He has more than 600 small and medium-sized steel mills to offer comprehensive sets of manufacturing traces or specialist non-normal gear.

According to the wants of consumers (Manufacturing and field situations), to give technical advice and other companies protection:

Overall program layout and thorough process tools structure, manufacturing technology

On-internet site products set up instructions or contracting

The creation line commissioning technological innovation advice or contracting

User workers specialized education

In the YWIN Group supplier overall performance, we are primarily based on the accuracy and mechanical performance of the items, creation scale requirements, versatile optimization of the mill models, warmth therapy gear, finishing products, a mixture of style out with a little expenditure, and strong competitiveness in the marketplace, effortless to run and sustain the production line. We manufacture a lot more than 100 creation strains are for the house owners of the region and even about the world to generate a very good economic rewards. We look forward to cooperate with a lot more new clients, produce value and performance.

A mature prolonged steel scorching-rolled production line production technology and full sets of products:

The ordinary bar generation line – rolling φ8-φ25 requirements sizzling-rolled ribbed metal bar, spherical metal bar. Steel: carbon steel, higher-top quality carbon metal, structural steel minimal-alloy steel ultimate rolling optimum velocity of fifteen m / s can singlet rolling, can also be lane rolling, yearly generation of ten-thirty million tons

Common wire rod manufacturing line – rolling φ5.five-φ10 (φ16) Specifications of sizzling-rolled ribbed metal wire rods, round metal rod steel: carbon steel, higher-quality carbon steel, structural steel low-alloy steel the final rolling optimum velocity of 25 m / s can singlet rolling, can also be lane rolling once-a-year generation of ten-30 million tons

Medium section steel (angle bar, channel metal, I-beam, spherical steel, flat metal) creation line – rolled the angle metal technical specs 8 # -16 # (or larger), ten # -18 # I-beam (or better) , channel 10 # -twenty # (or larger) flat steel one zero five × 22-150 × fifty five spherical metal Φ45-Φ160 (or better) metal: high-good quality carbon steel, carbon structural metal, low-alloy steel once-a-year manufacturing of 60-eighty million tons.

Small section metal (angle bar, channel steel, I-beam, flat steel) manufacturing line – rolled angle metal specs ≤ 10 # channel steel ≤ 12 # ≤ twelve # I-beam, flat metal ≤ 105 × 22 metal: high-top quality carbon steel, carbon structural steel, lower-alloy steel annual generation of ten-30 million tons.

Strip creation line – rolled strip technical specs width a hundred twenty five-450mm, one.5-20mm thick. Metal: large-top quality carbon metal, carbon structural steel, reduced-alloy steel yearly generation of twenty-50 million tons.

High-speed wire rod manufacturing line – the spherical metal rolling φ5.five-φ25 specs wire rod, very hot rolled the ribbed steel rod steel: high-good quality carbon steel, structural steel lower alloy metal, alloy steel, welding metal closing maximum rolling velocity of 95m / s singlet rolling two-lane rolling, yearly manufacturing of sixty-eighty million tons

Higher precision bar creation line – φ10-φ60 technical specs rolled round metal bar, scorching-rolled ribbed metal straight steel: higher-top quality carbon steel, structural metal lower alloy steel, alloy metal, and so on. last rolling pace 18m / s singlet rolling, 2,3,4 line segmentation rolling, once-a-year manufacturing of 60-100 million tons

YWIN-made according to the specific requirements of mature creation line:

Substantial-speed wire – large-precision composite rod generation line – to make high-velocity wire rod of substantial-precision round steel, sizzling-rolled ribbed metal bar, according to industry demand from customers, adaptable preparations for the manufacturing of versions, with an once-a-year output of up to 80 million metric tons.

Regular rod – line composite manufacturing line – can produce normal bars, wire round steel, scorching-rolled ribbed steel bar and wire rod, adaptable production kinds according to market need.

Rod – formed metal composite production line – can make bar, spherical bar, I-beam, angle, channel steel, flat steel. Adapt to market capability.

Strip – wire composite generation line – can create strip width of a hundred and forty-240mm thickness two.-3.5mm wire φ6.5-φ10. Steel: carbon steel, substantial-good quality carbon steel, reduced alloy metal annual output of 200,000 tons.

Spring flat steel – bar creation line – can produce spring flat (fifty-one hundred thirty) x (five-35), on behalf of the metal quality: 65Mn rolled ribbed metal bars φ10-φ14, on behalf of steels: 20MnSi

Unique alloy metal production line versatility – in accordance to the qualities of alloy metal rolling specific metal bar generation line layout, specification and creation corporations.

Mill reducer varieties of manufacturing traces, all varieties of cooling bed, finishing gear, roller conveyor by the Team developed and manufactured in its possess large-high quality products manufacturing plant. Our mill: short stress line mill, the shut substantial stiffness two roll mill, 3-roll opening mill, opening a two-roll mill shut two-roll mill accumulated much more than a thousand models previously on the market place, we have also created for rolling H-shaped metal universal mill. Apron on steels for all varieties of production lines supporting stepper rack type cooling mattress, ran trough steel stepping rack variety cooling bed, chain cooling bed, drive-pull cooling bed, has a straightforward structure, dependable procedure, value reduced characteristics. Affirmed by the consumers at residence and abroad.

Service Assurance

The YWIN Team the confront of hundreds of consumers around the globe have recognized productive and professional provider technique. According to the customers’ requirements and the actual situation to tailor the optimum options and offer the ideal top quality gear products, bear the advice of a total established of creation line gear of metallurgical machinery installation, commissioning, preserve manufacturing, and implementation of the monitoring services ensure spare areas provide, provide well timed and effective services to consumers close to the globe.

Pre-sale:

(1) clients with Division I professional to talk and comprehend the requirements of customers.

(two) complex personnel to the the user internet site plMontreal location to give the very best answer.

(3) the best design of the hardware based on client demand

Income:

(1) to provide the greatest quality products, the two sides of the acceptance of the solution

(two) to offer clients with a listing of spare areas

(3) to support clients produce the ideal on-internet site design plan.

Aftermarket:

(one) The to assign professional engineering workers, arrived at the scene to guide the set up and commissioning

(two) Prolonged-time period actual-time monitoring of consumer area devices use to supply timely and successful lifestyle-lengthy services to the user.

We have always been dedicated to delivering buyers with the best quality services, we will try to give far better service for customers.

Thanks for your viewing.