Tiny Floor-sort Horizontal CNC Lathe

For Machining Bearing, Flange,Cylinders, Long Shaft,Tire Mould, Railway Areas,Wheel Hub Turbine,and many others

one. Exceptional Characteristics:

1.) YWINized Configurations:

All elements of equipment are imported from overseas well-known brand names, this kind of as FANUC or SIMENS Management Method/ Schneider Electrical Control method, Japanese Bearing, ABB Motor& transmission box/equipment box, and so on. We can also configurate for each customer’s particular ask for and needs.

two.) This lathe adopts frequency manage technique as its principal drive method pushed by frequency manage motor, the velocity of major-shaft realizes stepless pace regulating, therefore having various speeds to satisfy rational cutting velocity demands for the machining of various kind of function-piece.

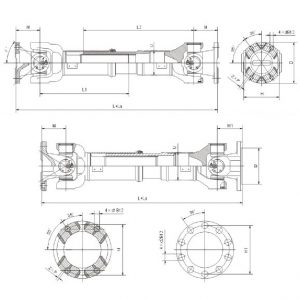

3.) This lathe consists of lathe mattress, selective headstock, tailstock, blade adapter, electric powered control technique, lubrication method, and so on. Selective headstock and tailstock are put in at the left and proper aspect of lathe bed respectively.

four.) The primary shaft can understand stepless speed regulating in a range of ten~300r/min and the primary spindle front bearing adopts large-precision double row cylindrical roller bearings, possessing substantial-diploma of rigidity and rotary precision and easy to modify.

5.) High Rigidity, Security and YWIN Maintenance: All castings are made of large-strength meehanite HT250. which is especially ideal for hefty slicing. All huge castings stand the check of annealing and vibration growing older and inside tension is removed, so the total precision is significantly enhanced and processed areas are found with large geometric precision.

Our Basic principle : Maximize YWINer’s Profitability under the least invest value.

Application: This is a CNC horizontal lathe which is suited for substantial-velocity steel and carbide chopping tool to implement coarse and fantastic inventory taking away and slicing on the outer cylindrical surface of roller of different components it also can be utilised for rough and complete machining of other shaft parts.

| Title | CK61100 | CK61125 | CK61160 | CK61200 | CK61250 | |

| Description | Unit | |||||

| Max. Swing more than bed | mm | 1000 | 1250 | 1600 | 2000 | 2500 |

| Max. Swing More than the skateboard | mm | 600 | 800 | 1200 | 1500 | 1800 |

| Max. Excess weight of Function-piece | T | 1 | 1 | 2 | 2 | three |

| Max. Length of Perform-piece | mm | 700 | seven-hundred | seven hundred | seven-hundred | seven-hundred |

| Gears of Spindle Velocity | / | Infinitely Variable Pace/stage-considerably less speed | ||||

| Range of Spindle Speed | r/Min | ten-three hundred | 10-200 | ten-one hundred sixty | ten-one hundred sixty | 4-80 |

| Chuck Diameter | mm | 800 | one thousand | 1250 | 1600 | 2000 |

| Bearing Diameter of Principal Entrance Shaft | mm | a hundred ninety | one hundred ninety | 220 | 220 | three hundred |

| X,Z-Axis Feed Variety | mm/Min | -3000 | ||||

| Horizontal Stroke | mm | five hundred | 650 | 800 | a thousand | 1250 |

| Longitudinal Stroke | mm | seven hundred | seven-hundred | seven-hundred | 700 | seven-hundred |

| Principal Driving Motor | Kw | Variable Frequency 11Kw-four | Variable Frequency 15Kw-four | Variable Frequency 22Kw-4 | Variable Frequency 30Kw-four | Variable Frequency 45Kw-four |

Rermarks:

1. The above five versions of Horizontal Lathe YWIN are the normal configurations, we can also style and manufacture customized lathe machines according to the user’s workpiece functions.

two. This series horizontal Lathe YWIN have been exported to Norway, Thailand, Romania, Iran, Russia, Chile for machining railway components, vehicle components, mining and metallurgy, shipping building, wind electrical power and other machinery business.

1. We provide specialist specialized coaching for users’ operators and maintenance workers to permit them to properly use and operate the lathe and have out standard routine maintenance.

2. Guarantee interval: A single year following acceptance of the lathe.

3. In scenario of any good quality problem found for the duration of operation, the factory will dispatch personnel to the user’s location inside of 48 several hours (domestic users) & inside of three days (Foreign YWINer) and the technical workers will not leave before resolving the malfuntion.

4. The company will freely provide diverse electrical and mechanical components for the obtained lathe timely in guarantee interval.

five. The firm will offer life time promise for the consulting services in conditions of software, routine maintenance, restore, renovation, and many others of equipments.

For a lot more details, please feel free to contact us. Thanks!