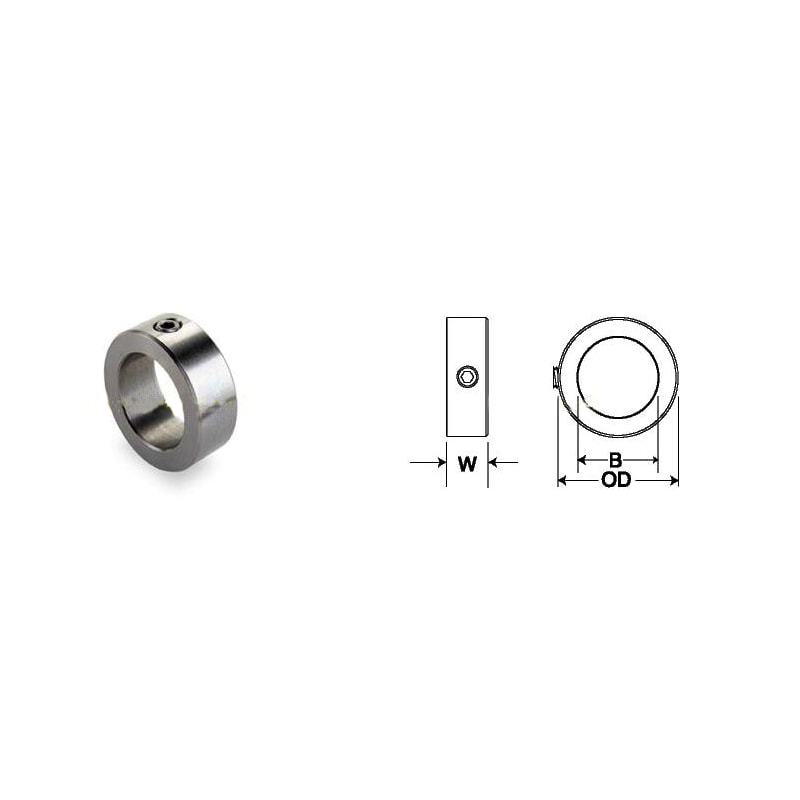

Description

- Forged socket set screws

- Bore tolerance:

+.01mm

+.05mm - Width tolerance:

+.08mm

-25mm

| PART NUMBER STEEL | |||||

|---|---|---|---|---|---|

| MSC-4-F | MSC-4-SS | 4 | 8 | 5 | M2.5X3 |

| MSC-5-F | MSC-5-SS | 5 | 10 | 6 | M3X4 |

| MSC-6-F | MSC-6-SS | 6 | 12 | 8 | M4X4 |

| MSC-8-F | MSC-8-SS | 8 | 16 | 8 | M4X4 |

| MSC-10-F | MSC-10-SS | 10 | 20 | 10 | M5X5 |

| MSC-12-F | MSC-12-SS | 12 | 22 | 12 | M6X6 |

| MSC-14-F | MSC-14-SS | 14 | 25 | 12 | M6X6 |

| MSC-15-F | MSC-15-SS | 15 | 25 | 12 | M6X6 |

| MSC-16-F | MSC-16-SS | 16 | 28 | 12 | M6X8 |

| MSC-18-F | MSC-18-SS | 18 | 32 | 14 | M6X8 |

| MSC-20-F | MSC-20-SS | 20 | 32 | 14 | M6X8 |

| MSC-22-F | MSC-22-SS | 22 | 36 | 14 | M6X8 |

| MSC-25-F | MSC-25-SS | 25 | 40 | 16 | M8X8 |

| MSC-28-F | MSC-28-SS | 28 | 45 | 16 | M8X10 |

| MSC-30-F | MSC-30-SS | 30 | 45 | 16 | M8X8 |

| MSC-32-F | MSC-32-SS | 32 | 50 | 16 | M8X10 |

| MSC-35-F | MSC-35-SS | 35 | 56 | 16 | M8X12 |

| MSC-38-F | MSC-38-SS | 38 | 56 | 16 | M8X10 |

| MSC-40-F | MSC-40-SS | 40 | 63 | 18 | M10X12 |

| MSC-45-F | MSC-45-SS | 45 | 70 | 18 | M10X12 |

| MSC-50-F | MSC-50-SS | 50 | 80 | 18 | M10X16 |

Feedback

1. Stainless Steel: SS201, SS303, SS304, SS316, SS416, SS420

2. Steel:C45(K1045), C46(K1046),C20

3. Brass:C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37), C28000(CuZn40)

4. Bronze: C51000, C52100, C54400, etc

5. Iron: 1213, 12L14,1215

6. Aluminum: Al6061, Al6063

7.OEM according to your request

Package

Wooden Case/Container and pallet, or as per customized specifications

Lead Time

15-25days samples. 30-45days offcial order

Certificate

ISO9001:2008 , ISO14001:2001,ISO/TS 16949:2009

- Mail/Skype:

- WhatsApp/Wechat:

Surface Treatment

Annealing, natural anodization, heat treatment, polishing, nickel plating, chrome plating, znic plating,yellow passivation, gold passivation, satin, Black surface painted etc.

Products Available

sprockt chains, pulley, shafts(axles, spline shafts, dart shafts),gears (pinions, wheels gear rack) bearing, bearing seat, bushing, coupling, lock assembly etc.

Processing Method

CNC machining, punch,turning, milling, drilling, grinding, broaching, welding and assembly

QC :

Technicians self-check in production,final-check before package by professional Quality inspector

Advantage

Quality first Service superior , Advanced equipment,Experienced workers,Perfect testing equipment