Description

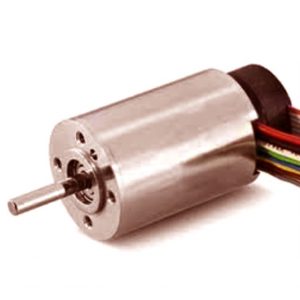

The magnetic field for a synchronous machine may be provided by using long lasting magnets made of neodymium-boron-iron, samarium-cobalt, or ferrite on the rotor. In some motors, these magnets are mounted with adhesive on the surface of the rotor core such that the magnetic field is radially directed across the atmosphere gap. In other designs, the magnets are inset into the rotor core surface area or inserted in slot machine games just below the surface. Another kind of Auto Chain permanent-magnet electric motor has circumferentially directed magnets positioned in radial slots that provide magnetic flux to iron poles, which create a radial field in the air flow gap.

The main application for permanent-magnet motors is in variable-speed drives where the stator is supplied from a variable-frequency, variable-voltage, electronically controlled source. Such drives are capable of precise speed and placement control. Because of the lack of power losses in the rotor, in comparison with induction electric motor drives, also, they are highly efficient.

Permanent-magnet motors can be designed to operate at synchronous swiftness from a way to obtain continuous voltage and frequency. The magnets are embedded in the rotor iron, and a damper winding is placed in slots in the rotor surface area to supply starting capability. Such a motor will not, however, have means of managing the stator power aspect.