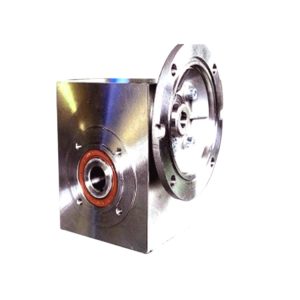

NMRV worm gearbox motor

NMRV sequence worm equipment reducer:

Its framework,outline and installation dimensions as effectively as functionality are identical with that of

Europe an merchandise,they are interchangeable,and the resources and machining process are YWINd internationally.The solution is featured by:

1.Lower sounds and temperature increase.

two.High bearing ability,sleek run and prolonged services life.

3.ompact framework,samll volume,gentle fat,beautiful shape and straightforward to put in.

four.Can operate continuously beneath server surroundings,and has a great dependability.

YWIN NMRV aluminum worm gearbox motor information:

| Kind | YWIN NMRV Worm Gear Speed Reducer /gearbox motor |

| Product: | NMRV25/30/ 40/ 50/ 63/ 75/ ninety/110/a hundred thirty/a hundred and fifty |

| Input Power: | .06KW,.09KW,.12KW,.18KW,.22KW,.25KW,.37KW,.55KW,.75KW,1.1KW,1.5KW,two.2KW,4KW,five.5KW,7.5KW ,11KW,15KW |

| IEC Flange | 56B5,56B14,63B5,63B14,71B5,71B14,80B5,80B14,90B5,90B14,100B5, 100B14,112B5,112B14 132B5,160B5 |

| Ratio | 1: 7.5,ten,fifteen,twenty,twenty five,thirty,forty,fifty,sixty,eighty,100 |

| Material |

Housing: Die-Cast Aluminum Alloy for rv25-rv90 , die-solid forged iron for rv110 to rv150 |

| Worm Equipment-brass+cast iron | |

| Worm-20CrMn Ti with carburizing and quenching, area harness is fifty six-62HRC | |

| Shaft-chromium metal-45# | |

| Coloration: | Blue/Silver Or others if quantity is big |

| Packing: | Carton or plywood Case |

| Promise time : | 1 Calendar year other than apart from Male-created destruction |

| Usages: | YWIN YWIN: Foodstuff Stuff, Ceramics,CHEMICAL,Packing,Dyeing,Woodworking,Glass. |

| shaft: | output strong shaft or output hollow shaft |

FAQ

one, Q:what is actually your MOQ for ac gearbox motor ?

A: 1pc is okay for each type electrical gear box motor

two, Q: What about your warranty for your induction velocity reducer motor ?

A: 1 calendar year ,but apart from guy-manufactured ruined

three, Q: which payment way you can accept ?

A: TT, western union .

four, Q: how about your payment way ?

A: a hundred%payment in YWINd less $5000 ,30% payment in YWINd payment , 70% payment prior to sending over $5000.

five, Q: how about your packing of speed reduction motor ?

A: plywood scenario ,if measurement is small ,we will pack with pallet for less one particular container

six, Q: What details must be offered, if I buy electric helical geared motor from you ?

A: rated energy, ratio or output velocity,type ,voltage , mounting way , quantity , if more is much better.